You need thousands of high-quality stickers, but digital printing gets too expensive at that volume. You worry about inconsistent colors and fuzzy details on such a big and important order.

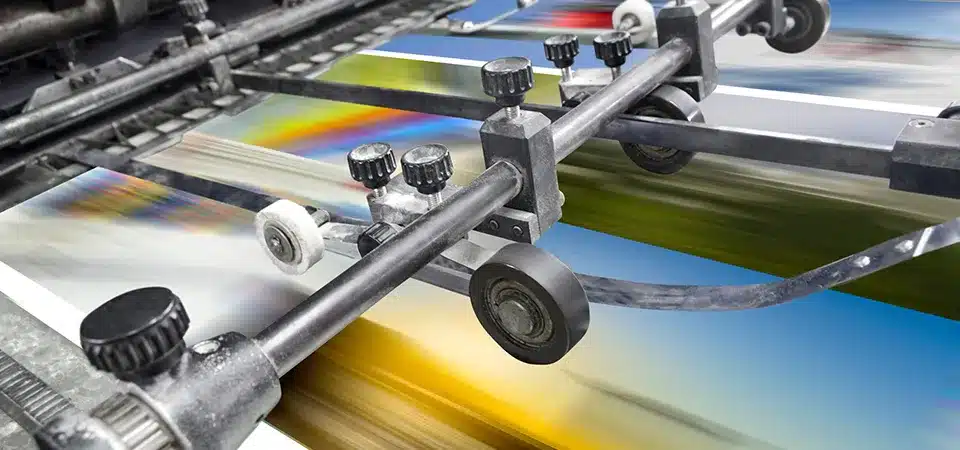

Lithographic printing, also called offset printing, is a high-volume technique that uses metal plates and rubber blankets to transfer ink. It delivers superior quality, precise color matching, and a low per-unit cost on large jobs.

In my sticker business, litho printing is the secret weapon for clients who are scaling up. It’s a classic printing method that has been perfected over a century, and for good reason. It delivers incredible quality that digital printing often struggles to match at a large scale. But, it's not the right choice for every single project. Understanding how it works is the key to knowing when to use it to make your brand look its best. Let's break it down.

What is litho printing, really?

The term "offset lithography" sounds complex and maybe a little intimidating. You're not sure how it's different from the digital printing you know, which makes it hard to choose.

Litho printing uses the simple principle that oil and water don't mix. A design is put on a metal plate. Ink (oil) sticks to the design, while water keeps the rest of the plate clean. This inked design is then transferred to paper.

I remember the first time I saw a litho press running. It was a massive machine and looked so complicated. But my mentor explained the core oil-and-water concept, and it all clicked. It’s like a very precise, high-speed stamping process. The key is in the name "offset." The ink doesn't go directly from the metal plate to the paper. It's first transferred, or "offset," onto a soft rubber blanket. Then, the blanket presses the ink onto the paper. This indirect step does two amazing things. First, it gives you incredibly sharp and clean images. Second, the flexible rubber can press ink onto a wide variety of surfaces, even lightly textured ones, without any loss in quality. It’s this offset process that makes the final print so consistent and professional.

What are the pros and cons of litho printing?

You need to choose a print method but you're getting conflicting advice. The wrong choice could cost you time and money, or leave you with thousands of low-quality stickers.

The main benefit is superior image quality and a very low cost-per-sticker on large orders. The main drawback is the high initial setup cost and longer turnaround time, making it a poor choice for small jobs.

Deciding between litho and digital is a daily conversation I have with my clients. It really comes down to balancing quality, quantity, and cost. A client once wanted just 100 stickers with a specific Pantone brand color. I had to explain that making the metal plates for a litho run would cost hundreds of dollars, far more than the stickers themselves. We used a digital press, which was a great solution for that quantity. But for another client who needed 50,000 labels for their new sauce bottles, litho was the only logical choice. The cost per label was just a few cents. Here is a table to help you decide.

| Pros | Cons |

|---|---|

| Superior Quality & Detail | High Setup Costs |

| Excellent Color Matching (Pantone) | Not for Short Runs |

| Very Low Per-Unit Cost at High Volume | Longer Turnaround Times |

| Works on a Wide Range of Materials | No Variable Data (e.g., unique names) |

How does the lithographic print process work step-by-step?

You hear about "plates" and "press setup" but the actual process is a mystery. This makes it hard to understand why it takes longer and costs more upfront than digital printing.

The litho process has three main stages: pre-press, where the design is made into plates; printing, where ink is transferred to paper; and finishing, where the prints are cut. Each stage requires expertise and time.

The "click and print" convenience of a desktop printer has made us forget how complex traditional printing is. It's a craft that requires several careful steps. Understanding them helps you appreciate why the quality is so high.

Step 1: Pre-Press and Plate Making

This all happens before the press even starts running. We take your digital artwork file and separate it into its core colors, usually Cyan, Magenta, Yellow, and Black (CMYK). We then use a machine to etch each color's design onto its own thin aluminum plate. If you need a special Pantone spot color, it gets its own plate, too.

Step 2: Press Setup and Printing

Each plate is loaded onto a cylinder in the massive printing press. The press automatically applies ink and a water solution. The ink sticks only to the image on the plate. Then, the press roars to life. Sheets of paper or vinyl are fed through at high speed, with each color unit printing its part of the design. The image is transferred from the plate to the blanket, then to the paper.

Step 3: Finishing

The printed sheets come out perfectly printed but need to dry. Once the ink is set, we move the stacks of sheets to our finishing department. Here, they are cut down to the final sticker size and shape, often using a laser or a metal die-cutter.

Are there different types of litho printing?

You see terms like "sheet-fed" and "web offset" but don't know what they mean. You worry you might choose the wrong service for your sticker project.

Yes, the main types are sheet-fed and web offset. Sheet-fed uses precut sheets of paper and is best for high-quality jobs like stickers. Web offset uses huge rolls of paper for things like newspapers.

This is an important distinction that determines the quality and cost of your project. While they both use the same offset principle, they are designed for very different jobs.

Sheet-fed Offset

This is the method we use in my shop for premium stickers and labels. The press is fed individual sheets of paper or vinyl one by one. This process allows for incredible control and precision. The print quality is generally the highest available, which is why it's used for fine art books, luxury packaging, and high-end product labels. It’s perfect for jobs from a thousand to a few hundred thousand pieces.

Web Offset

This is for massive-volume printing. The press is fed by a gigantic roll of paper that can be miles long. It runs incredibly fast and is used to print things like newspapers, magazines, and catalogs where millions of copies are needed quickly. It's extremely cost-effective at that scale, but the quality is typically a small step below sheet-fed.

Waterless Printing

This is a newer, more eco-friendly method. Instead of using water to repel ink, it uses a special silicone-coated plate. This reduces chemical use and saves a lot of water.

What materials are used in offset litho printing?

You love the idea of litho quality but aren't sure if it will work on your chosen sticker material. You worry you’ll have to compromise on your vision of a durable, glossy label.

Litho printing is very versatile. It works beautifully on most papers, paperboard, and certain vinyls or plastics. For stickers, I always recommend smooth, coated paper stocks or specialized vinyl to get the sharpest result.

The rubber blanket is the key here. It allows us to print on a wider range of materials than many other methods. For stickers, the choice of material is critical to getting that premium look.

Coated Papers

These papers have a smooth, slick surface that doesn't absorb much ink. This means the ink dot stays crisp and clean on the surface, which is exactly what you want for fine details and vibrant colors. Glossy and semi-gloss papers are my go-to choices for high-quality paper labels.

Vinyl and Synthetic Substrates

For stickers that need to be waterproof, tear-proof, and durable, we use vinyl. It's important to use a vinyl material that is specifically designed for offset litho printing. It needs to handle the press mechanics and ink chemistry. When printed, these vinyl stickers are incredibly tough and look amazing—perfect for products that will be handled a lot or exposed to moisture.

A Note on Texture

While litho can print on some textured materials, I always tell my clients that for stickers with very small text or intricate lines, a smooth surface is always best. The smoother the road, the cleaner the ride.

What is litho printing typically used for?

You know litho is for high-volume jobs, but you're unsure if it fits your specific product. You need to know where this printing method truly excels in the real world.

Litho printing is the industry standard for any high-volume project where quality and color consistency are essential. Think magazines, books, brochures, commercial packaging, and large runs of premium product labels.

Once you know what to look for, you'll see litho printing everywhere. It’s the engine of the commercial print world.

Commercial Publications

Every time you pick up a professionally published book, a glossy magazine, or a colorful catalog, you are almost certainly holding a product of offset lithography. Its ability to produce millions of identical, high-resolution copies makes it the only choice.

Product Packaging

Look at the box for your smartphone or the folding carton for your favorite cereal. That printing is done on large flat sheets using lithography, then it's cut, folded, and glued. Brands need the color of their logo to be exactly the same on every box, in every store, worldwide. Litho delivers that consistency.

High-Volume Labels and Stickers

This is my specialty. When a cosmetics brand needs 50,000 labels for their lotion bottles, litho is the answer. It ensures that the first label printed looks identical to the 50,000th. This consistency builds powerful brand recognition and trust with customers.

How can litho printing be environmentally friendly?

You care about sustainability, but you've heard that traditional printing can be wasteful. You worry about choosing a method that doesn't align with your brand's eco-friendly values.

Modern lithography is much greener than it used to be. Printers now use soy-based inks, alcohol-free chemicals, recycled paper, and water-saving technologies to reduce their environmental impact significantly.

This is a question I get from clients more and more, and I love it. As a business owner, I am also focused on reducing my environmental footprint. The good news is that the entire litho industry has made huge progress.

Better Inks and Chemicals

The old petroleum-based inks are being replaced by vegetable and soy-based inks. These are made from renewable resources and are much less harmful to the environment. We also use low-VOC (volatile organic compound) press chemicals, which improves air quality for my team and the planet.

Waste and Energy Reduction

Good planning is key. We often group several smaller jobs onto one large press sheet to minimize paper waste. Modern presses are also far more energy-efficient than older models. Many shops also use closed-loop systems that recycle cleaning solvents over and over.

Responsible Paper Choices

The choice of paper is one of the easiest ways for a brand to make a difference. We offer a wide range of high-quality papers made from recycled content or from responsibly managed forests (FSC-certified). These materials print beautifully and show your customers you care.

What is the future of lithographic printing?

With the growth of digital printing, you might think lithography is becoming outdated. You're wondering if you're choosing an old technology for your brand's long-term needs.

The future of litho is about speed, automation, and integration with digital. New hybrid presses can combine litho's quality and cost-effectiveness with digital printing's flexibility, offering the best of both worlds.

People often ask me, "Will digital printing replace litho?" I always say no. They aren’t competitors anymore; they are becoming partners. The future is about using the right tool for the right job, and sometimes, using them both together.

Automation and Efficiency

The biggest change in new litho presses is automation. Plate changing, color adjustments, and cleanup are now done by the machine's computer. This drastically cuts down on setup time and paper waste, which makes litho a viable option for even smaller run lengths than before.

Hybrid Printing Technology

This is where things get really exciting. Imagine you need 20,000 product labels. We can print the main design and logo using lithography for perfect color and low cost. Then, that same sheet can run through a digital print head to add a unique QR code or serial number to each individual label. This hybrid approach is powerful.

Data-Driven Manufacturing

Modern presses are "smart." They collect data on every job to optimize performance, predict maintenance needs, and ensure consistency. This efficiency and reliability mean better quality and more stable pricing for you, the client. Lithography isn't fading away; it's getting smarter, faster, and more connected.

Conclusion

Litho printing remains the champion for high-volume jobs that demand quality. For large sticker orders needing perfect color and crisp detail, it delivers unmatched professionalism and value every time.