You need a batch of custom stickers, but the pricing seems all over the place. Without a clear budget, you risk either overpaying or getting a cheap product that won't last.

Printing 1,000 standard 3x3 inch vinyl stickers typically costs between $100 and $300. The final price depends on factors like material, size, the complexity of the cut, and any special finishes. For most bulk orders, the per-sticker cost drops to just $0.10 to $0.30.

As someone who runs a sticker printing business, I handle quotes like this every single day. The question I get most often is, "How much for 1,000 stickers?" While I can give you a quick estimate, the real answer is in the details. The choices you make about your sticker's look and feel are what determine the final cost. Let's break down exactly what goes into that price so you can order with confidence.

What Are the Biggest Factors that Influence Sticker Cost?

You've seen some printers advertise incredibly low prices. But you're worried there's a catch, and you don't want to get a bad-quality product by trying to save a few dollars.

The final cost is driven by five key factors: the sticker's size, its material, the complexity of its shape, the finish or laminate applied, and the quantity. Each of these elements can significantly raise or lower your price per sticker.

In my experience, most of the cost comes from the raw materials and the machine time needed to produce the order. A larger sticker simply uses more vinyl and ink, which increases the price. Similarly, a complex die-cut shape takes the laser or blade longer to cut than a simple circle. When I work with my clients, I often help them find the perfect balance between their design vision and their budget. Sometimes, a small tweak, like slightly reducing the size or simplifying a cutline, can result in significant savings without compromising the sticker's impact.

Breaking Down the Major Cost Factors

Here is a simple breakdown of how each choice affects your quote. Understanding these will help you manage your budget effectively.

| Factor | How It Affects Cost | Pro Tip for Saving Money |

|---|---|---|

| Size | Larger stickers cost more because they use more material and ink. The price difference between a 2x2" and a 4x4" sticker can be substantial. | Stick to standard sizes like 2" or 3" if possible. They are versatile and cost-effective. |

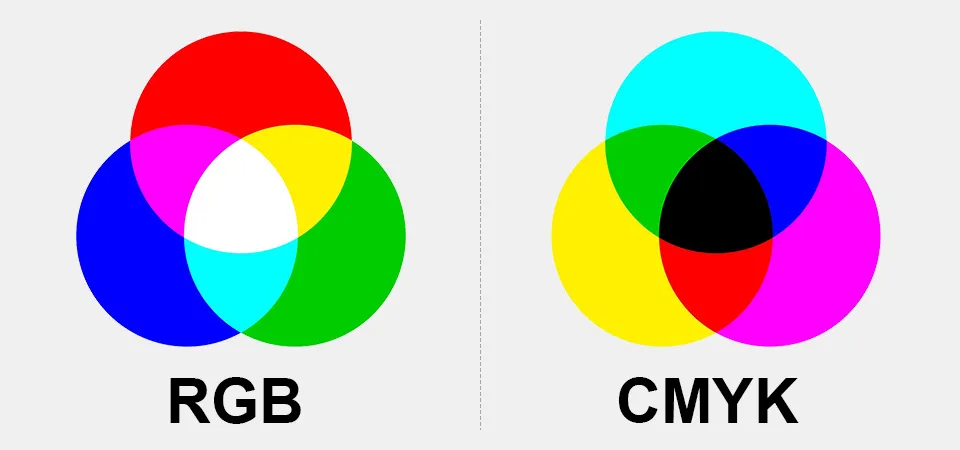

| Material | Standard vinyl is the baseline. Specialty materials like holographic, clear, glitter, or eco-friendly vinyls are premium materials that cost more. | White vinyl is durable, waterproof, and perfect for over 90% of applications. Start there. |

| Shape | Standard shapes (squares, circles) are cheapest. Custom die-cut shapes require more precise machine work and can increase the price by 20-50%. | If your design is complex, try to simplify the cut path to reduce machine time and cost. |

| Finish | A protective laminate adds durability. A standard gloss or matte finish adds a small cost, while a special finish like UV laminate adds more. | A basic glossy finish offers good protection and a vibrant look at a minimal cost. |

| Quantity | The more you order, the lower the per-sticker price. 1,000 stickers are significantly cheaper per piece than 100 due to economies of scale. | If you know you'll need more stickers later, order them all at once to get the best bulk discount. |

How Do Different Sticker Materials Affect the Final Price?

You want your stickers to look amazing, but the list of materials is confusing. Choosing the wrong one could mean you've either overpaid or ended up with a sticker that peels off in a week.

Standard white vinyl is your most affordable and versatile option. Specialty materials like holographic or clear vinyl will increase your cost by 20-50% because the base material is more expensive to produce and may require special printing processes.

The material is the foundation of your sticker. It determines not just the price, but also the durability, look, and best use case. At my shop, we print on a wide range of materials, but I always tell new clients to start with the basics unless they have a specific need. For example, a holographic finish is my absolute favorite for brands that want to grab attention at events, but for a simple product label, classic white vinyl is often the smarter financial choice. It's all about matching the material to the job it needs to do.

A Look at Popular Sticker Materials

Let's compare some of the most common options and their impact on your budget.

White Vinyl (The Workhorse)

This is the industry standard for a reason. It's affordable, waterproof, UV-resistant with a laminate, and prints colors beautifully. It's perfect for laptops, water bottles, product packaging, and almost any other use you can think of. It provides the best value for your money.

Holographic Vinyl (The Eye-Catcher)

This material has an iridescent, rainbow-like finish that changes with the light. It makes designs pop and gives them a premium, futuristic feel. The material itself is more complex to manufacture, making it a more expensive option. It's fantastic for special editions, artist stickers, and brands with a bold aesthetic.

Clear Vinyl (The Minimalist)

Clear stickers are printed on a transparent background, creating a sleek "no-label" look. This is ideal for placing on colored surfaces, glass, or product packaging where you want the product underneath to show through. The cost is slightly higher than white vinyl due to the transparency requirements.

Eco-Friendly Materials (The Sustainable Choice)

Materials like recycled paper or biodegradable vinyl are becoming more popular. They are a great way to show your brand's commitment to sustainability. These options typically raise the cost by about 10-25% due to the specialized manufacturing process.

Why Should You Order 1,000 Stickers from a Professional Printer?

You're wondering if you could save money by printing the stickers yourself at home. But you're worried about the hidden costs, the time involved, and whether the quality will be good enough.

For a quantity of 1,000, professional printing is far more cost-effective and reliable. Our industrial machines offer huge economies of scale, dropping the per-sticker price, while ensuring perfect color, precise cuts, and weather-resistant durability that DIY setups can't match.

I've seen many small business owners try the DIY route, and while it seems cheaper upfront, the costs add up quickly. You need to buy a quality printer, a cutting machine like a Cricut, expensive ink cartridges, and sheets of vinyl paper. After all that, you still have to spend hours printing, cutting, and weeding each sticker by hand. The quality is often inconsistent, and the stickers are rarely waterproof or scratch-resistant. With a professional printer, you get a perfect, durable product delivered to your door for a lower per-sticker cost, saving you both time and money.

Professional Printing vs. DIY Printing (for 1,000 Stickers)

| Feature | Professional Printing | DIY Printing at Home |

|---|---|---|

| Per-Sticker Cost | Low ($0.10 - $0.30) due to bulk material discounts. | High ($0.05 - $0.15 in materials, plus ink and labor). |

| Upfront Investment | $0 | $500+ for a decent printer, cutter, and software. |

| Quality & Consistency | Perfect color matching, precise die-cuts, uniform results. | Colors can vary, cuts can be inconsistent. |

| Durability | Waterproof, scratch-resistant, UV-protected vinyl. | Typically not waterproof unless laminated by hand. |

| Labor & Time | Zero. Just upload your design and wait. | Many hours of printing, cutting, and manual labor. |

Conclusion

Printing 1,000 stickers is affordable when you understand the key factors. Focus your budget on the size, material, and finish that best fit your brand's needs.