You have a great idea for a sticker but are stuck facing minimum orders of a thousand pieces. This feels wasteful, expensive, and completely drains your budget.

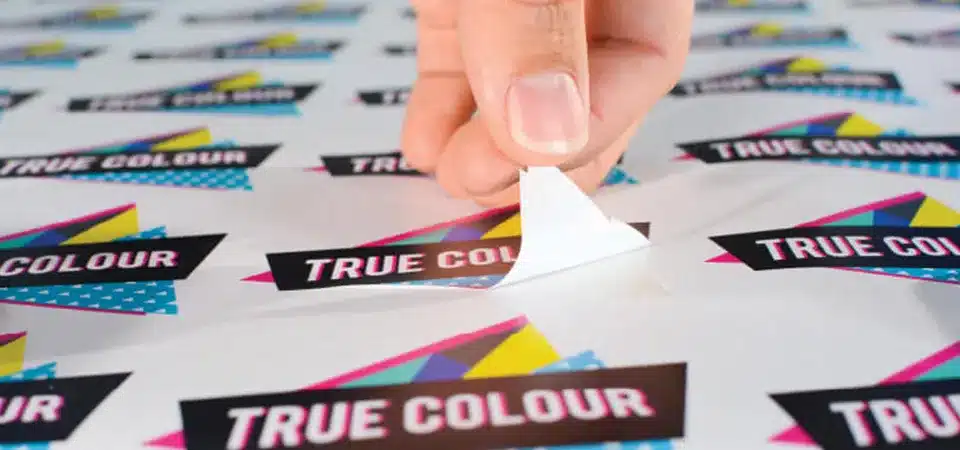

Small run sticker printing unlocks your brand's potential by allowing you to order professional-quality, custom stickers in any quantity you need. It uses digital technology to make printing flexible, fast, and affordable for everyone, from startups to artists.

In my years running a sticker printing business here in China, I have seen so many brilliant ideas get stopped in their tracks by high costs and large minimums. That's why I've built my shop around the power of small-run printing. It's a total game-changer, allowing me to help creators and entrepreneurs test their ideas, launch new products, and build their brands with confidence. It's not just about printing stickers; it's about making professional branding accessible. This guide will walk you through everything you need to know to take advantage of it.

What Exactly Defines Small or Short Run Sticker Printing?

You hear the terms "short run" and "small batch," but it sounds like confusing industry jargon. You're not sure if it is the right and professional choice for your project.

Short-run printing simply means producing small quantities of stickers, typically from one to a few hundred pieces. Unlike bulk printing, it uses digital methods to deliver high-quality, cost-effective results on a small scale, making custom stickers accessible to everyone.

The best way to understand short-run printing is to look at the features that define it. For decades, printing meant using huge offset presses that required expensive custom metal plates for each color, forcing customers into buying thousands of units. Short-run printing uses a completely different, modern approach that is built for agility. It’s not a compromise on quality; it’s just a smarter way to print for today’s needs.

Here’s a breakdown of the features that truly define what short-run sticker printing is:

| Defining Characteristic | How It Defines Short Run Printing |

|---|---|

| Digital Technology | It uses digital printers and laser cutters. This eliminates the need for expensive setup (like metal plates or dies), which is why it's affordable for small quantities. |

| No Minimum Order (MOQ) | You can order the exact quantity you need, even just one sticker. This is its most revolutionary feature, offering zero risk and no wasted inventory. |

| Speed and Agility | Because the process is digital, turnaround is incredibly fast (often 1-5 days). You can react quickly to market trends or needs without waiting weeks for a bulk order. |

| Design Flexibility | It allows for printing multiple designs within a single order. You can test different looks or offer a wider variety of products without placing separate, expensive orders. |

Just last week, an Etsy artist came to me wanting to test four new sticker designs. With short-run printing, she ordered just 25 of each. This was impossible with old methods but is now a standard, everyday request in my shop.

Is Short Run Sticker Printing the Right Choice for You?

You have a sticker idea, but you worry your project is too small for a professional printer. This hesitation might prevent you from creating valuable branding or merchandise for your cause.

Short-run printing is perfect for small businesses, startups, artists, and event organizers. It's the ideal solution for product prototypes, limited edition merchandise, or personalized gifts when you need pro quality without a large upfront investment.

Over the years, I've noticed that the people who get the most out of short-run printing are the ones who value flexibility and creativity. They are the hustlers, the creators, and the people making something new and exciting. If you fall into one of these groups, this is probably the best printing method for you.

For Small Businesses & Startups

When you're starting out, cash is tight. You can't afford to spend a thousand dollars on packaging that might change in six months. I recently helped a new hot sauce company create labels for three different flavors. We printed just 100 labels for each. This allowed them to launch their product line with a professional look for a very low cost.

For Artists and Creators

Artists, designers, and social media creators often have many different designs they want to sell. Short-run printing allows them to offer a whole catalog of stickers without having to hold a huge, expensive inventory. They can order 25 of one design and 50 of another, all in one go. It's perfect for conventions or online stores.

For Events and Personal Use

From personalized stickers for a child's birthday party to branded stickers for a corporate event, short-run is the answer. Event organizers for conferences, product launches, and weddings need custom materials, but they don't need thousands of leftovers. It's the smart, waste-free choice.

What Are the Real Advantages of Printing in Small Batches?

You assume ordering a small number of stickers means paying a very high price for each one. This mistaken belief might stop you from exploring new and exciting designs that could grow your brand.

The main advantages are having no minimum order quantities (MOQs), facing low financial risk, and enjoying incredible flexibility. You can test multiple designs at once, get a fast turnaround, and reduce waste by ordering precisely what you need.

When clients switch from shopping for bulk printing to trying our short-run services, they are always shocked by the benefits. It doesn't just save them money on one order; it fundamentally changes how they approach their creative and business projects. Here are the main advantages that make it such a game-changer.

- No Minimum Order Quantities (MOQs): This is the big one. You can order 50 stickers, 10 stickers, or even just one single sticker if that's all you need. You are not forced into a large purchase.

- Low Risk for New Projects: Want to test a new logo, a new product, or a new piece of merchandise? Order a small batch. If it doesn't sell or the design needs changes, you've only spent a small amount of money.

- Reduce Waste and Unused Stock: How many of us have seen boxes of old, outdated promo materials sitting in a storage room? Short-run printing lets you order with precision, so you use what you buy.

- Flexibility to Test Multiple Designs: You can print multiple designs within a single order. If you have four designs and you're not sure which will be most popular, you can order 25 of each and let your customers decide.

- Fast Turnaround: Because digital printing doesn't require a long setup process, orders can be printed and shipped very quickly. There is no waiting in line behind a massive bulk order.

What Sticker Types and Finishes Can You Get in a Small Run?

You think choosing a small run means you are stuck with basic, flimsy paper stickers. You worry that you won't be able to get the professional materials and finishes your brand deserves.

You can get almost any type of professional-grade sticker. This includes durable vinyl (in matte, gloss, or clear), custom die-cut shapes, kiss-cut sheets, and even specialty finishes like holographic, metallic foil, and waterproof options.

This is one of the biggest myths I have to debunk for new customers. Thanks to modern digital printing and cutting technology, you have access to a huge range of materials and finishes, even for a tiny order. You are not sacrificing quality or choice. In my shop, the options are nearly identical for an order of 50 or 50,000.

Core Materials and Custom Shapes

The most popular choice is vinyl because it's durable, waterproof, and feels very professional. From there, we can cut it into any shape you can imagine.

- Vinyl Stickers: Available in a vibrant gloss, a smooth and modern matte, or a sleek transparent finish.

- Die-Cut Stickers: These are cut precisely to your design's shape, creating a premium sticker that's perfect for handing out.

- Kiss-Cut Stickers: The sticker is cut to a custom shape, but remains on a square backing. This makes it easier to peel and protects delicate edges.

- Sticker Sheets: We can also put multiple different kiss-cut designs on a single sheet, which is perfect for artists and planners.

Specialty Finishes

Want your sticker to really stand out? Digital printing makes these incredible options accessible for small batches:

- Holographic & Iridescent

- Gold & Silver Foil

- Brushed Metallic Textures

- Heavy-Duty Waterproof & UV-Resistant Laminates

How Does the Technology Behind Short Run Printing Actually Work?

You're curious how it's possible to affordably get just one custom-shaped, holographic sticker. The technology seems complex, but the idea behind it is actually very straightforward.

It works by combining high-resolution digital printing with computer-guided laser cutting. This automated workflow eliminates the need for expensive traditional plates or custom metal dies, allowing for fast, flexible, and affordable production of any quantity.

The reason shops like mine can offer this service is because we've invested in a fully digital workflow. It comes down to two key pieces of modern technology that work together perfectly to make small runs possible and affordable.

1. Digital Printing

Traditional sticker printing uses an "offset" press. To print a design, you have to chemically etch it onto a metal plate—one plate for each color. This process is slow and expensive. It's why you have to order thousands of stickers to make the setup cost worthwhile. Digital printing, on the other hand, works more like a high-end desktop printer. It takes a digital file (like a PDF) and prints it directly onto the sticker material with incredible quality. There are no plates and almost no setup time.

2. Digital Laser Cutting

After printing, the stickers need to be cut. The old way required creating a custom "die"—a sharp metal cookie-cutter of your design that could cost hundreds of dollars. Today, we use digital cutters. A computer-controlled laser beam cuts any shape imaginable with perfect precision, based directly on your artwork file. There are no die costs, which means any custom shape is possible, even for a single sticker.

What Is the Step-by-Step Process for Ordering Your Stickers?

You're ready to print, but the ordering process seems complicated. You're worried you will miss a crucial step and end up with stickers that don't match your vision.

Ordering is a simple process: gather your artwork, select your specs (material, size, quantity), approve the digital proof your provider sends you, complete payment, and wait for your high-quality stickers to arrive.

Ordering custom stickers for the first time is much easier than you might think. We've streamlined the process in my shop to be as straightforward as possible. Here is a typical step-by-step guide to placing your first small-run order.

Preparing Your Artwork

Before you order, get your design file ready. For best results, it should be a vector file (AI, PDF, SVG) or a high-resolution 300 DPI raster file (PNG, PSD). Remember to design in CMYK color mode and include a 1/8-inch "bleed" area around your art to avoid white edges. If this sounds confusing, don't worry—my team can always help.

The Ordering Process

- Select Your Specifications: Use the website's order form to choose all your options. This is where you'll pick the material, size, quantity, and shape.

- Upload Your Artwork: Attach your finished design file to the order.

- Approve Your Digital Proof: This is a crucial step! We will send you a final digital preview of your sticker showing the colors and cut lines. Review it carefully. If everything looks perfect, approve it.

- Complete Your Order & Payment: Once you approve the proof, you'll complete the checkout process.

- Receive and Review Your Stickers: Your order will go into production and be shipped to you quickly. Now you can get ready to use them for your project!

How Can You Use Small Run Stickers to Boost Your Project?

You know you can print stickers easily now, but you're looking for fresh ideas. You need inspiration on how to use them effectively for your business, event, or creative project.

Use them for limited-edition product packaging, merchandise for creators, or stationery for events. They are perfect for branding startups on a budget or for creating custom rewards for crowdfunding campaigns and internal teams.

The flexibility of small-run printing has unlocked so many creative applications. I'm constantly inspired by what my clients create with the freedom it gives them. Here are some of the most popular and effective use cases I see every day in my shop.

For Product Branding & Packaging

- Test New Products: Create labels for a small batch of seasonal coffee, a new line of cosmetics, or a test run of hot sauce.

- Startup Branding: A new business can create professional-looking packaging without committing to thousands of printed boxes. A simple sticker on a stock bag or box looks fantastic.

- Thank You Stickers: Add a branded "Thank You" sticker to seal tissue paper or include in an online order. It's a small touch that makes a big impact.

For Artists & the Creator Economy

- Sticker Packs: Artists can bundle several of their designs into a themed sticker pack to sell online or at conventions.

- Patreon & Crowdfunding Rewards: Stickers are a low-cost, high-value reward for supporters and backers.

For Events & Campaigns

- Wedding Stationery: Use custom stickers to seal invitations, decorate favor boxes, or create personalized labels for wine bottles.

- Company Swag: Boost team morale with custom stickers for laptops featuring the company logo or an inside joke.

FAQs

You still have a few specific questions before you're ready to order. You're wondering about size limits, color matching, and how quickly you can get your stickers in hand.

You can order almost any size, from tiny dots to huge decals. You can include many designs in one order, but on-screen RGB colors will look slightly different from printed CMYK colors.

I answer these questions all the time, so I've gathered the most common ones here to give you quick, clear answers from my experience running a print shop.

-

What is the smallest/biggest sticker I can order?

With laser cutting, we can make stickers as small as 0.5 inches and as large as several feet wide. The only real limit is what's practical for your design. -

Can I have different designs in a single order?

Yes! This is a core benefit of short-run printing. You can order 100 total stickers and ask for 25 of four different designs. -

Will my colors match what I see on screen?

They will be very close, but rarely a perfect 100% match. Your screen uses RGB light, while printers use CMYK ink. For the most accurate results, design in CMYK. If color is absolutely critical, we can print a physical sample for you. -

Can stickers be waterproof/UV resistant?

Absolutely. If you order our vinyl stickers with a protective laminate, they will be highly durable, waterproof, and resistant to fading in the sun for years. -

How fast can I get my stickers?

Very fast. Because the digital setup is instant, production for small runs usually takes 5-7 business days in my shop. -

What if my design isn’t print-ready?

Most good printing companies have a design team that can help. My team and I can often fix common issues, create a cut line for you, or provide templates to get you started.

Conclusion

Small run sticker printing has removed old barriers, offering unmatched flexibility, cost savings, and creative freedom to businesses and creators of all sizes. Try it for your next project.