In modern printing and branding, stickers are an essential tool for communication and marketing. Whether for personal brands or large corporations, stickers are used to grab attention, convey messages, or add value. Among the many types of stickers, kiss cut and die cut stickers are the two most common. These two types differ significantly in their production process, design thinking, and application scenarios. Understanding these differences can help consumers, designers, and businesses make more informed decisions.

What are Kiss Cut Stickers?

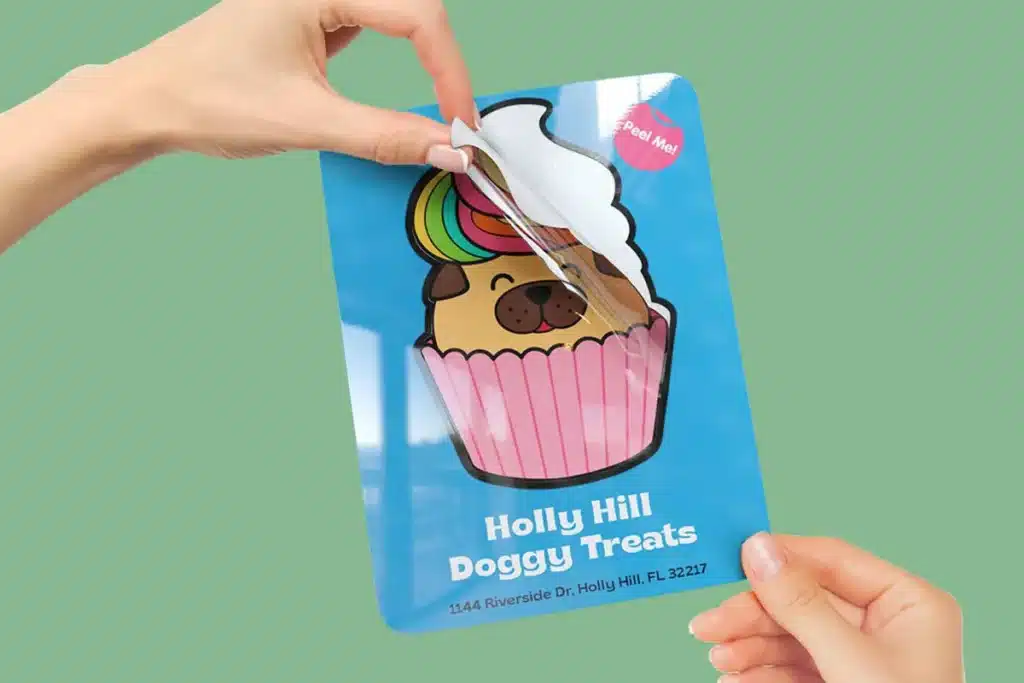

Kiss cut stickers are a type of sticker that involves a light cut. Unlike die cut stickers, kiss cut stickers are only cut through the top layer, meaning the cut lines are on the surface (i.e., the printed layer) rather than the bottom layer (i.e., the backing paper). As a result, the edges of the sticker do not fully detach from the backing paper and remain part of a whole sheet. The process is called "kiss cutting" because the blade "kisses" the top layer of the sticker without cutting through the backing paper.

How Are Kiss Cut Stickers Made?

The process of making kiss cut stickers typically includes the following steps:

Design and Preparation

In design software (such as Adobe Illustrator, CorelDRAW, or other professional design programs), the sticker artwork is created. Designers must ensure that the design and cut lines are clear, ensuring only the top layer is cut.

The cut lines are typically marked using specific “cut marks” so that machines can accurately identify the cutting locations.

Printing Stage

High-quality printers are used to print the design onto specific sticker paper. Common sticker materials include paper, PVC, polyester, or other adhesive materials.

At this point, the printed stickers are still attached to a larger backing sheet, keeping the shape of the entire sticker intact for easy handling and storage.

Kiss Cutting Stage

After cutting, the stickers are re-arranged and packaged. Most kiss cut stickers are distributed in bulk to customers, companies, or businesses. A laser cutter or die-cutting machine is used to lightly cut the surface of the sticker, ensuring that only the top layer is cut into the desired shape, while the backing paper remains intact.

This light cutting process ensures that the sticker can be easily peeled off without damaging it. The backing paper remains complete and can be used for future handling.

Packaging and Distribution

After cutting, the stickers are re-arranged and packaged. Most kiss cut stickers are distributed in bulk to customers, companies, or businesses.

Benefits of Kiss Cut Stickers

Easy Removal

Kiss cut stickers are designed for easy removal without tearing or damaging the design. This feature prevents any harm to the design when the sticker is peeled off the backing paper.

Space Efficient

Because the stickers don’t fully detach from the backing paper, designers can fit more stickers on the same sheet. This optimizes storage and packaging space, reducing shipping and storage costs.

Ideal for Mass Production

The production process for kiss cut stickers is relatively simple, making them ideal for mass production and quick distribution. This makes them highly suitable for promotional activities by businesses.

Protection for the Design

During the cutting process, since the stickers remain attached to the backing paper, the designs are not exposed to external elements. This reduces the risk of environmental factors affecting the sticker's artwork.

Uses of Kiss Cut Stickers

Brand Marketing: Many companies use kiss cut stickers as part of their branding campaigns, producing large quantities of stickers to give away for free to increase brand visibility.

Social Media Campaigns: Numerous social media challenges or campaigns involve giving away kiss cut stickers to boost engagement and interaction. For example, a brand might send out kiss cut stickers featuring their logo to fans to encourage sharing and reposting.

Personalized Decorations: Kiss cut stickers are also used for personal decoration. Many people apply custom kiss cut stickers to notebooks, phones, luggage, and other personal items.

What are Die Cut Stickers?

Die cut stickers are stickers that are cut into specific shapes using a die (a specialized mold). Unlike kiss cut stickers, die cut stickers are typically fully detached from the backing paper, and each sticker's shape is usually unique, following the exact design pattern. The cutting process for die cut stickers is more precise, allowing for complex designs and shapes to be created with high accuracy.

How Are Die Cut Stickers Made?

The process of making die cut stickers is more intricate than that of kiss cut stickers, but it provides higher precision and greater design freedom. The typical steps include:

Design Phase

Similar to kiss cut stickers, die cut stickers are designed using professional design software. Designers have the freedom to define the sticker's shape, artwork, and cutting path precisely.

Printing Phase

The design is printed onto high-quality materials. These materials can vary depending on the intended use, including adhesive paper, polyester film, PVC, or other durable self-adhesive materials.

Die Cutting Phase

Using a specialized die-cutting machine or laser cutter, the sticker is precisely cut along the contours of the design. The die-cutting machine's blade follows the design exactly, cutting each sticker out individually from the sheet.

Post-Processing Phase

After cutting, the die cut stickers often undergo a cleaning process to remove any excess material.The individual stickers are then separated and prepared for packaging.

Benefits of Die Cut Stickers

Complex Shapes and Customization

Die cut stickers can be cut into almost any shape, from simple geometric forms to intricate custom designs. This flexibility allows for highly creative and unique sticker designs.

Stronger Visual Impact

Since each die cut sticker is cut to a specific shape, they tend to have a stronger visual impact compared to kiss cut stickers. Their unique shapes often draw more attention and stand out better, making them more effective in catching consumers' eyes.

Durability

Die cut stickers are typically made from more durable materials with stronger adhesives, making them suitable for long-term application on various surfaces like cars, laptops, and other outdoor or high-use objects.

Uses of Die Cut Stickers

High-End Brand Promotion: Die cut stickers are often used for promoting premium brands. Their precision and unique shapes allow these stickers to convey the brand's distinctiveness and high-quality image.

Limited Edition Products: Many artists or brands release limited edition die cut stickers as exclusive collectibles or unique memorabilia, adding a sense of rarity and special appeal.

Personalized Decoration: Due to their customizable nature, die cut stickers are commonly used for personalizing items such as backpacks, electronics, water bottles, and more, allowing individuals to showcase their style and creativity.

Key Differences Between Kiss Cut and Die Cut Stickers

| Feature | Kiss Cut Stickers | Die Cut Stickers |

|---|---|---|

| Cutting Method | Cuts only through the top layer, leaving the backing paper intact | Fully cut through, separating the sticker from the backing paper |

| Shape and Design | Best for simple shapes, often used for mass production | Ideal for complex or unique shapes, offering more customization |

| Ease of Use | The backing paper remains intact, making storage and transport easier | Ready to use immediately without extra handling required |

| Typical Applications | Great for brand promotion, giveaways, and small batch production | Commonly used for premium brands, event memorabilia, and personalized products |

Which Sticker is Right for You?

Choosing between kiss cut and die cut stickers ultimately depends on your needs and budget:

Personalized and Premium Appeal: If you’re looking for unique shapes, visual impact, or to enhance your brand identity, die cut stickers are the better choice. They can help your brand stand out and make a stronger impression.

Limited Budget: If you need to produce a large volume of stickers at a lower cost, kiss cut stickers are likely the more economical choice. They are ideal for mass production and are perfect for marketing campaigns, giveaways, and other large-scale uses.

Design Tips for Creating Eye-Catching Stickers

To design stickers that truly grab attention, designers should follow these key principles:

1.Choose the Right Materials and Printing Methods

Invest in high-quality materials and printing techniques to ensure your stickers are durable and vibrant. Well-made stickers maintain their colors and hold up to wear and tear, making them last longer and look sharper.

2.Keep the Design Simple and Clear

Simplicity is key. Focus on the main message or theme of the design. Avoid overcomplicating things, as a clean, clear design makes the sticker easier to understand and more visually appealing.

3.High-Contrast Colors

Using contrasting colors can make your sticker pop. Bright, bold colors catch the eye, especially when they stand out against the background, creating a visual impact.

4.Shape and Space Usage

Be mindful of white space. It’s important to balance your design by leaving enough space around the artwork to make it feel organized and easy to process. Overcrowding can overwhelm the viewer.

Final Thoughts

Whether you’re a brand, designer, or individual consumer, understanding the differences between kiss cut and die cut stickers can help you make a more informed decision. Kiss cut stickers are perfect for large-scale production and cost-effective marketing campaigns, while die cut stickers offer greater customization and visual impact—making them ideal for showcasing your brand's personality and premium image.

By selecting the right type of sticker and combining it with creative design, you can create stickers that are not only practical but also eye-catching, helping to strengthen your brand image and stand out in a crowded market.

FAQ

What’s the main difference between kiss cut and die cut stickers?

- Kiss Cut Stickers: Only the top layer (the printed layer) is cut, leaving the backing paper intact. The stickers remain connected to the backing paper.

- Die Cut Stickers: The sticker is fully cut out from the backing paper, often with more complex shapes, providing a unique and precise design.

What are the best uses for kiss cut stickers?

Kiss cut stickers are ideal for:

- Brand Promotion and Marketing: Due to their simple production process and lower cost, they’re great for bulk production, giveaways, and event swag.

- Personalized Decoration: Perfect for customizing personal items such as notebooks, phones, luggage, etc.

- Social Media Campaigns: Brands can distribute kiss cut stickers to increase fan engagement and brand visibility.

What are the advantages of die cut stickers?

The benefits of die cut stickers include:

- Custom Design: Can be cut into any shape, perfect for unique and creative designs.

- Premium Look: With smooth, precise edges, die cut stickers offer a polished, high-quality appearance, ideal for luxury brands or special events.

- Durability: Die cut stickers are often made with more durable materials, making them great for long-term use on surfaces like cars, laptops, or other outdoor items.

How are kiss cut stickers made?

The process for making kiss cut stickers includes:

- Design & Preparation: Create the design and ensure the cutting path aligns with the desired shape and size.

- Printing: Print the design on specialized sticker paper.

- Kiss Cutting: Use a laser cutter or die-cut machine to lightly cut the top layer, leaving the backing paper intact.

- Packaging: After cutting, the stickers are repositioned and packaged for distribution.

How are die cut stickers made?

The process for creating die cut stickers typically involves:

- Design: Custom patterns are created, and cutting shapes are defined.

- Printing: The design is printed on high-quality materials.

- Die Cutting: The sticker is precisely cut out using a die to separate it from the backing paper.

- Post-Processing: Any excess material is removed, ensuring the final stickers are clean and flawless.

Should I choose kiss cut or die cut stickers?

Choosing between kiss cut and die cut stickers depends on your needs:

- Kiss Cut Stickers: If you need mass production with a limited budget, kiss cut stickers are a cost-effective choice.

- Die Cut Stickers: If you need unique shapes or a high-end visual effect, die cut stickers are the way to go, especially for custom or premium brand promotion.

What are the benefits of kiss cut stickers?

The advantages of kiss cut stickers include:

- Easy to Remove: The stickers stay intact with the backing paper, making them easy to peel off without damage.

- Space-Efficient: With bulk production, more stickers can be packed into a smaller space, reducing shipping costs.

- Ideal for Large-Scale Distribution: Because of their simple and efficient production process, kiss cut stickers are perfect for large marketing campaigns.

What are the benefits of die cut stickers?

The benefits of die cut stickers include:

- High Customization: Can be cut into any shape, ideal for personalized and creative designs.

- Professional Look: Die cut stickers generally have a more refined appearance, perfect for high-end brands or special events.

- Durability: Made from strong materials with superior adhesive, making them suitable for long-lasting outdoor use.

How can I ensure the durability of my stickers?

To ensure the durability of your stickers:

- Choose high-quality materials and adhesives, especially for outdoor use.

- For long-lasting outdoor stickers, look for waterproof, UV-resistant, and weatherproof materials.

- Die cut stickers are often more durable than kiss cut stickers because they typically use tougher materials designed for extended use.

How deep is the cut on a kiss cut sticker?

The cut on a kiss cut sticker is very shallow—only through the top printed layer. The backing paper remains intact, allowing the sticker to peel off easily without damaging the design.

How complex can die cut stickers be?

Die cut stickers can be very complex and custom-shaped, allowing for intricate designs. From simple geometric shapes to highly detailed custom artwork, die cutting can accommodate virtually any design, making it perfect for artistic or unique patterns.

What shapes can kiss cut stickers come in?

Kiss cut stickers are typically made in simpler shapes such as circles, squares, and rectangles. However, designers can arrange multiple stickers on a single sheet in creative ways to form varied designs.

What industries use die cut stickers?

Die cut stickers, with their premium and customizable nature, are widely used in industries like:

- Brand Promotion: Luxury brands, limited edition products, or special events often use die cut stickers for promotional purposes.

- Automotive & Device Decoration: For car decals, laptop skins, and protective stickers.

- Art & Creative Industries: Artists, designers, and crafters use die cut stickers to showcase their unique creations.

Are kiss cut stickers suitable for outdoor use?

Kiss cut stickers are suitable for short-term outdoor use, but they generally don’t offer the same durability as die cut stickers. Most kiss cut stickers are designed for indoor use or temporary displays. For long-term outdoor use, opt for waterproof and UV-resistant materials to increase longevity.