You spend years building a reputation for quality, only to have customers doubt your product is genuine because the packaging looks generic. It is frightening to realize that without a secure seal, anyone could open your product, tamper with it, or swap it out for a fake before it even reaches the buyer.

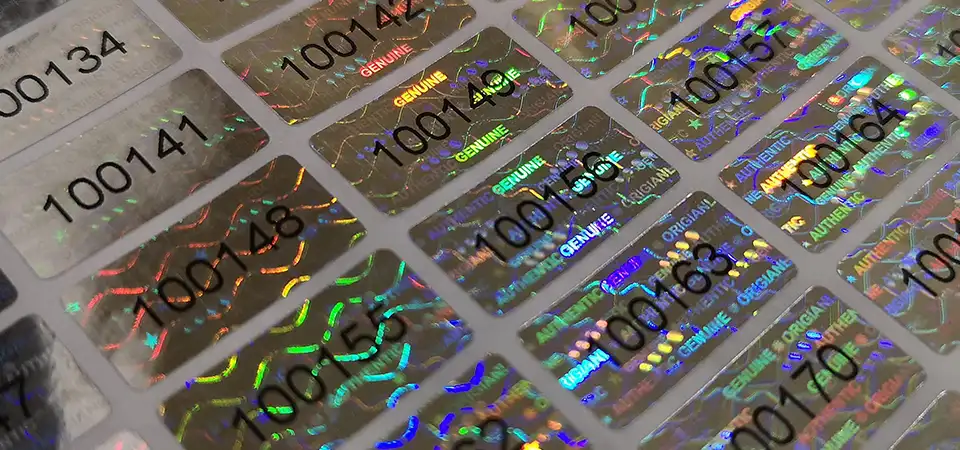

Holographic authenticity stickers are detailed optical security seals designed to verify that a product is genuine and has not been tampered with. They serve as a visual guarantee to the customer, using complex 3D light patterns that cannot be copied by standard digital printers or photocopiers.

In my line of work, I often meet business owners who think a simple paper label is enough to seal a box. I have to explain that a paper label can be heated up with a hair dryer and peeled off without a trace. A holographic authenticity sticker is different. It is not just about looking shiny; it is about acting as a lock. When a customer sees that rainbow glint, they know the item came directly from your factory to their hands.

What are holographic authenticity stickers?

You encounter these shiny, shifting labels on everything from software packages to pharmaceutical bottles and wonder what makes them special.

Holographic authenticity stickers are security labels made from metalized film that display a three-dimensional image or pattern when light hits them. Unlike standard stickers that use ink, these rely on light diffraction to create visual depth, making them difficult for counterfeiters to replicate and easy for customers to identify.

In my factory, we distinguish clearly between "decorative" holograms and "authenticity" holograms. A decorative text is just a cool effect. An authenticity sticker is a tool. It acts as a certificate of birth for your product.

When you look at a standard sticker, you see ink on the surface. When you look at a holographic authenticity sticker, you are looking into layers of light. These stickers usually contain specific patterns like guilloche lines (complex intersecting curves like you see on banknotes) or micro-text that is too small for the naked eye to read.

The primary function here is trust. In markets like electronics or cosmetics, where knock-offs are common, this sticker is the only thing telling the consumer, "This is safe." I often tell my clients that this sticker is psychological. It signals to the buyer that the brand cares enough to invest in security. If a counterfeiter wants to copy your product, they now have to replicate a complex optical device, not just photocopy a box.

How are holographic authenticity stickers made?

You might assume these stickers are printed with special metallic ink, but the process is far more industrial and complex than standard printing.

Holographic authenticity stickers are not printed with ink; they are made by embossing microscopic grooves into a metallic film using a high-pressure laser master shim. This process, called "origination," burns interference patterns into the material, which then diffracts light to create the specific images and colors you see.

I want you to understand that making these stickers is closer to minting coins than printing flyers. You cannot make a true security hologram on an inkjet printer. This high barrier to entry is exactly why they work for security.

The process starts with a Master. We use lasers to record a light interference pattern onto a photosensitive glass plate. This captures the depth and movement. We then create a nickel "shim" or stamp from this glass master.

In production, we take a roll of thin film (usually PET) and coat it with a special lacquer. The nickel shim is heated and pressed into this lacquer with immense pressure. It physically stamps millions of tiny grooves—nanometers deep—into the plastic. Finally, we vacuum-coat the film with a microscopic layer of aluminum. This aluminum acts like a mirror, reflecting light through those tiny grooves to create the rainbow 3D effect. Because the image is physically embossed into the plastic, a scanner cannot read it correctly. If you try to scan it, the light scatters, and you just get a black blob.

| Production Step | Description | Security Function |

|---|---|---|

| Origination | Laser recording of pattern | Creates unique optical fingerprint |

| Electroforming | Creating nickel master shim | Ensures consistent replication |

| Embossing | Stamping grooves into film | Impossible to print with ink |

| Metallizing | Aluminum coating | Makes the light diffraction visible |

What are the use cases of holographic authenticity stickers?

You know these stickers are secure, but you may not be sure if they are necessary for your specific product or industry.

Brands use holographic authenticity stickers primarily for anti-tampering seals, proving product origin, and securing official documents. They are essential in industries where safety and brand reputation are at risk, such as pharmaceuticals, electronics, and high-end retail, serving as a frontline defense against fraud.

I work with clients across many sectors, and while the technology is the same, the application changes based on the threat they are facing. Here is how we break down the three main uses.

Anti-tampering

This is the most common use I see for food, beauty, and tech products. You place the holographic sticker over the seam of a box or the cap of a jar. The goal here is physical security. We use "frangible" materials for these stickers. If someone tries to peel the sticker off to open the box, the sticker destroys itself. It might leave behind a "honeycomb" pattern or the word "VOID" on your packaging. This tells the customer immediately that the package is not safe. It stops people from swapping a cheap item into an expensive box in a retail store.

Product authentication

This is about brand value. I have authorized resellers who need to prove they are selling the real thing. For example, a sports memorabilia company selling signed baseballs. Without the hologram, it is just a ball with ink on it. With the hologram (often with a unique serial number), it is a verified collectible. The hologram links the physical object to the company’s identity. It allows customers to spot a fake on a shelf instantly because the fake usually lacks the depth and movement of the real hologram.

Official documents

This is the highest level of security. Think of ID cards, diplomas, or certificates. Here, the hologram prevents alteration. If you put a transparent holographic laminate over a photo on an ID card, you cannot change the photo without destroying the holography. We use very complex designs here, often with "hidden images" that you can only see with a laser pointer, to ensure that tickets and passes cannot be forged by scammers.

Can I use holographic stickers as authenticity stickers?

You might be wondering if you need to buy expensive custom security labels or if you can just use the generic shiny stickers available online.

Yes, you can use any holographic sticker as an authenticity seal, but true security requires a custom master with unique features rather than generic "stock" holographic vinyl. While decorative holographic stickers offer a basic visual deterrent, they can be easily purchased and copied by counterfeiters, whereas custom holograms are unique to your brand.

I often have small business owners ask me if they can just print their logo on "rainbow vinyl" and call it a security sticker. The answer is yes, but with a warning.

If you are a local bakery sealing cookie boxes, a generic holographic material with your logo printed on it is fine. It looks professional and shows you sealed the package. This is what we call "Stock Holography." The pattern (like stars or dots) is generic, and anyone can buy that same material roll. It offers light security because a casual thief won't have that sticker handy, but a determined copier can easily buy the same vinyl.

For "True Security," you need a "Custom Master." This is where we create a unique hologram just for you. The background pattern includes your logo embedded into the light diffraction itself. We add hidden layers that only you know about. This is expensive to set up because of the master plate fee. I recommend this path only if you are losing money to counterfeits or selling high-value items. A generic holographic sticker is better than a paper sticker, but a custom holographic sticker is the only way to be 100% sure the label originated from you.

| Feature | Stock Hologram | Custom Security Hologram |

|---|---|---|

| Pattern | Generic (Dots, Rainbow) | Unique Logo/Design |

| Availability | Anyone can buy | Restricted to Brand Owner |

| Cost | Low | High (Setup Fees) |

| Security Level | Low/Medium | High/Military Grade |

Conclusion

Holographic authenticity stickers protect your brand by using embossed light patterns to verify origin; while generic options exist, true security comes from custom masters that stop tampering and counterfeiting.