You want amazing custom apparel, but traditional printing is expensive and has too many rules. It feels impossible to get small batches of full-color designs without breaking the bank.

Choose Direct to Film (DTF) for its incredible versatility. It prints vibrant, full-color, detailed designs on nearly any fabric, including cotton, polyester, and dark colors. With no setup fees, it's perfect for small orders, offering a soft, durable finish that other methods can't match.

As a sticker and custom print expert, I’ve seen technologies come and go. But DTF printing has completely changed how I help my clients. It solves so many old problems. It bridges the gap between quality, cost, and flexibility. Let's look at why this method might be the perfect choice for your next project.

What Exactly is DTF Printing?

You've probably heard the term "DTF," but it sounds technical. You're not sure how it works or if it's right for you. Let's make it simple.

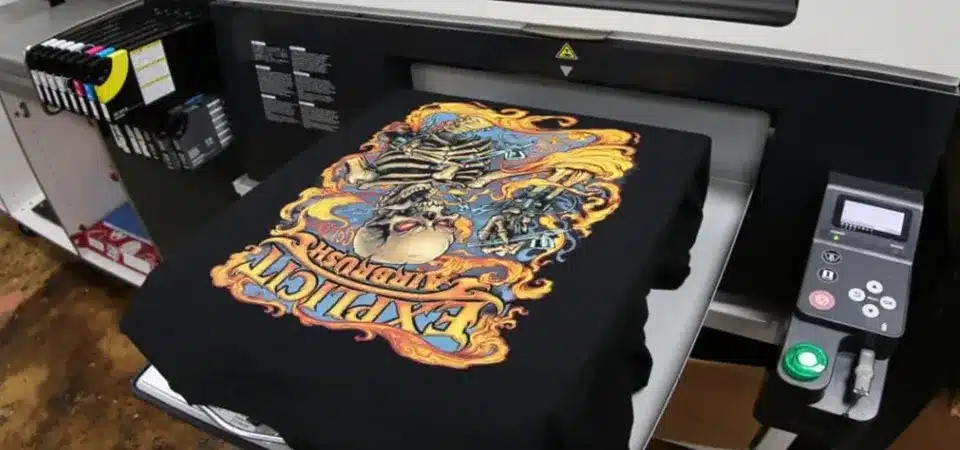

DTF, or Direct to Film, is a process where a design is printed onto a special piece of film. A powder adhesive is applied to the back of the ink. Then, the film is heat-pressed onto a garment, transferring the complete, durable design.

When I first brought a DTF system into my shop, I was amazed by its simplicity and power. It’s a very clever process that gives you incredible results. It's not as complex as it sounds, and it allows me to say "yes" to projects I used to turn away.

The DTF Process Step-by-Step

Let's walk through how a design goes from a computer screen to your shirt.

- Print on Film: First, we take your digital design and print it onto a special, clear PET film. The printer lays down the colors first, and then a layer of white ink on top. This white layer is key to making the colors pop on any garment color.

- Apply Powder Adhesive: While the ink is still wet, the printed film passes through a machine that sprinkles it with a hot-melt adhesive powder. The powder sticks only to the wet ink, not the clear parts of the film.

- Cure the Film: The film and powder then go through a small heat tunnel. This melts the powder and turns it into a smooth, even layer of adhesive on the back of the design. Now, the transfer is ready to be stored or used immediately.

- Press onto Garment: We position the finished film on the t-shirt, hat, or bag. Using a heat press, we apply heat and pressure. This activates the adhesive, bonding the design permanently to the fabric fibers.

- Peel and Reveal: After a few seconds, we peel the film away. All that's left on the garment is your beautiful, vibrant design. It feels soft and is ready to wear.

What are the Key Benefits of DTF Printing?

You need prints that are vibrant, durable, and won't cost a fortune. Other methods make you choose between color, quantity, or fabric. DTF offers huge advantages without forcing you to compromise.

DTF’s main benefits are its power to print on any fabric (cotton, polyester, leather), create vivid full-color designs at no extra cost, maintain a soft feel when worn, and provide excellent durability that resists cracking and fading.

The single biggest reason my clients love DTF is its freedom. For years, people had to accept the limitations of other printing methods. DTF removes those limits. It’s a true game-changer for small businesses and creative individuals.

Why DTF is a Game-Changer

- Prints on Anything: This is the biggest benefit. Screen printing and DTG work best on cotton. Sublimation only works on polyester. DTF doesn't care. I've used it to print on 100% cotton t-shirts, 100% polyester sports jerseys, cotton/poly blend hoodies, canvas tote bags, and even leather patches. This flexibility means you can use one printing method for your entire product line.

- Vibrant, Unlimited Colors: With methods like screen printing, every color in your design adds cost because it requires a new screen. DTF printing is digital, so it can print millions of colors, fine details, and photographic gradients just as easily as a one-color logo. There are no extra fees for complexity.

- Durable and Soft: The finished DTF print has a soft, smooth feel. It’s more flexible and less likely to crack than some thick screen prints. Because the ink bonds so strongly to the fabric, the designs hold up incredibly well in the wash. We've run wash tests in my shop, and our DTF prints still look great after 30+ cycles.

- Cost-Effective for Small Runs: Since there are no screens to create, there are no setup fees. This makes DTF extremely affordable for small orders. If you need just 10 shirts for an event or want to test a new design without a big investment, DTF is the perfect solution.

How does DTF compare with Traditional Methods?

DTF sounds promising, but how does it really stack up against the methods you already know? Picking the wrong print type can cost you time and money. Here’s a direct comparison.

DTF bridges the gap between traditional methods. It has more fabric versatility and lower setup costs than screen printing, better vibrancy on darks and polyesters than DTG, and works on cotton, which sublimation can't do. It combines the best features into one process.

I use all of these technologies in my shop, so I know their strengths and weaknesses firsthand. Each one is a useful tool, but you have to pick the right tool for the job.

Screen Printing

This is the classic, workhorse method. It involves pushing ink through a mesh screen onto the fabric.

- Pros: Extremely durable, cost-effective for very large volumes (100+ items), vibrant colors.

- Cons: Expensive setup costs for each color, not practical for photos or complex designs, becomes very expensive for small orders.

Direct to Garment (DTG)

This is like an inkjet printer for fabric. It sprays water-based ink directly into the garment's fibers.

- Pros: Incredible softness (you can't feel the ink), great for detailed photos, no setup fees.

- Cons: Works best on 100% cotton, struggles with polyester, colors can look dull on dark garments without proper pre-treatment.

Sublimation Printing

Here, the ink turns into a gas under heat and permanently dyes the fabric fibers.

- Pros: Absolutely permanent with zero feel, extremely vibrant.

- Cons: Only works on white or light-colored 100% polyester fabric. It cannot print on cotton or dark materials.

Comparison at a Glance

| Feature | DTF (Direct to Film) | Screen Printing | DTG (Direct to Garment) | Sublimation |

|---|---|---|---|---|

| Fabric Types | Cotton, Polyester, Blends, Leather | Most fabrics, best on cotton | Primarily 100% Cotton | 100% Polyester (light colors) |

| Best Fabric Color | Any color, including darks | Any color | Light colors | White or light colors |

| Feel | Soft, flexible layer on top | Can be a thick layer | Very soft, no feel | Zero feel, dyed into fabric |

| Durability | Very Good, stretchy | Excellent, very long-lasting | Good, can fade over time | Excellent, permanent |

| Best For | Small batches, full-color designs | Large batches, 1-4 color designs | One-offs, photos on cotton | Sportswear, polyester items |

| Setup Cost | None | High | None | None |

Why Choose DTF for your Printing Needs?

You're still weighing the options, unsure which is best for your specific project. Choosing wrong leads to disappointment. Let's make it clear when DTF is the absolute best choice.

Choose DTF when you need vibrant, full-color designs on a wide variety of fabrics, especially for small to medium orders. It’s the most flexible and cost-effective modern option without sacrificing quality, feel, or durability.

I guide my clients through this decision every day. The right choice depends entirely on what you want to create. DTF has become my go-to recommendation for the majority of custom apparel projects because it solves so many common problems. A client recently came to me with a beautiful, detailed painting they wanted on just 15 black hoodies for their art club. Screen printing would have been too expensive with all those colors, and DTG wouldn't be as vibrant on their poly-blend hoodies. DTF was the perfect solution. They were thrilled with the results.

Choose DTF if...

- You have a design with many colors, gradients, or fine details.

- You need to print the same design on different types of items (e.g., cotton shirts and polyester bags).

- You are ordering a small quantity (from 1 to 100 pieces).

- You are printing on dark-colored garments and want your colors to be bright and opaque.

- You want a print that is both durable for washing and has a soft, flexible feel that won't crack.

- You need a fast turnaround without paying high setup fees.

If your project fits several of these points, then DTF is almost certainly your best option.

Why choose Stickerprintingchina?

You know you want DTF, but you need a printing partner you can trust. Poor quality prints and unreliable service can ruin your project and waste your money. Let us handle your printing with expertise.

At Sticker Printing China, we offer expert DTF printing using our own advanced equipment for consistent quality. We specialize in low minimums and fast turnarounds, providing hands-on support to make your brand's custom apparel and stickers look amazing.

I've been in the custom printing industry for over a decade. I don't just sell printing; I live and breathe the technology behind it. When we decided to offer DTF, I spent months testing machines and materials to ensure we could deliver a product I was proud to put my name on. We're not a middleman; we control the entire process.

Here's what that means for you:

- True Expertise: We understand how to optimize your designs for DTF to get the most vibrant colors and sharpest details. We can guide you on what will and won't work.

- In-House Quality Control: All of our printing is done right here in our own facility in China. We use top-of-the-line equipment that we maintain ourselves. This gives us full control over quality from start to finish.

- We Support Small Businesses: As a business owner myself, I know how important it is to start smart. We welcome low-minimum orders. You don't need to order 500 pieces to get started. We're happy to help you grow your brand, one great product at a time.

- Fast and Reliable: Because we manage everything in-house, we can meet tight deadlines. We are more than just a printer; we are your partner in creation.

Conclusion

DTF printing provides unmatched versatility and vibrant color for on-demand apparel. It's the modern, flexible choice for bringing your creative designs to life on almost any fabric.