You want a custom sticker but the terms are confusing. "Die cut" sounds complex and maybe expensive. You just want your awesome design to look as good as possible.

A die cut sticker is cut precisely to your design's unique shape, including the backing paper. A regular sticker is printed on a standard shape like a square or circle, often leaving a blank background around your design.

I get this question almost every day in my sticker business. The truth is, the cutting style you choose completely changes the look, feel, and even the perceived value of your final product. It's the difference between a simple label and a custom piece of branding. Let's break down each type so you can pick the perfect one for your project.

What are custom die cut stickers?

Your cool logo gets lost on a boring square sticker. It doesn't pop or look professional, and it fails to show off the quality of your brand.

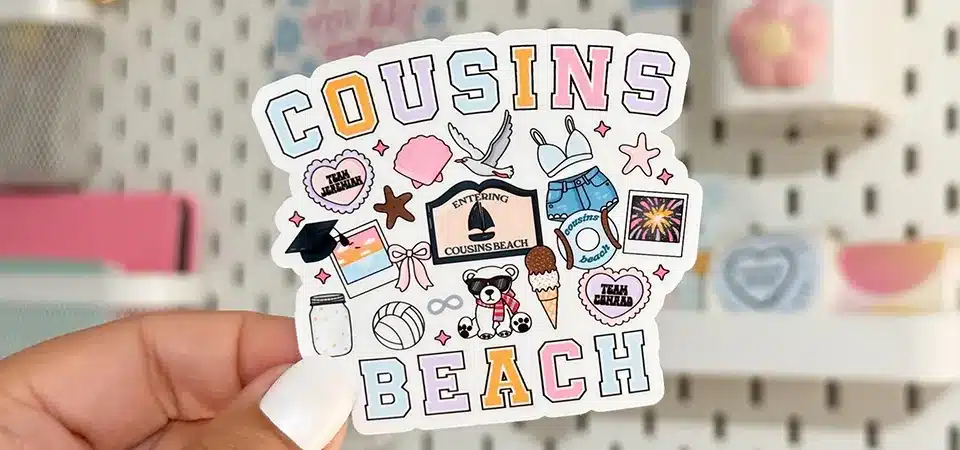

Custom die cut stickers are cut through both the vinyl and the backing paper to perfectly match the outline of your design. This creates a custom-shaped, individual sticker with no extra border.

"Die cut" means the sticker is a standalone item, trimmed to your design's exact shape. Think of it like a cookie cutter slicing through dough. In my shop, we use high-precision lasers that act as a digital "die" or cutter. This allows us to cut even the most intricate shapes. When we're done, the sticker itself is the shape of your design. There's no extra, distracting white or clear material around it. I remember a client who designed an amazing, detailed logo of a phoenix for her new business. A simple rectangular sticker would have looked cheap and lazy. We made a die-cut version, and the final product was stunning. The shape itself told a story. It felt like a premium badge she could hand to customers, not just a sticker. That's the power of a die cut—it makes the shape part of the art.

When to get a die cut sticker?

You have stickers, but they don't get noticed. They just blend in with everything else and fail to grab the attention you need for your brand or event.

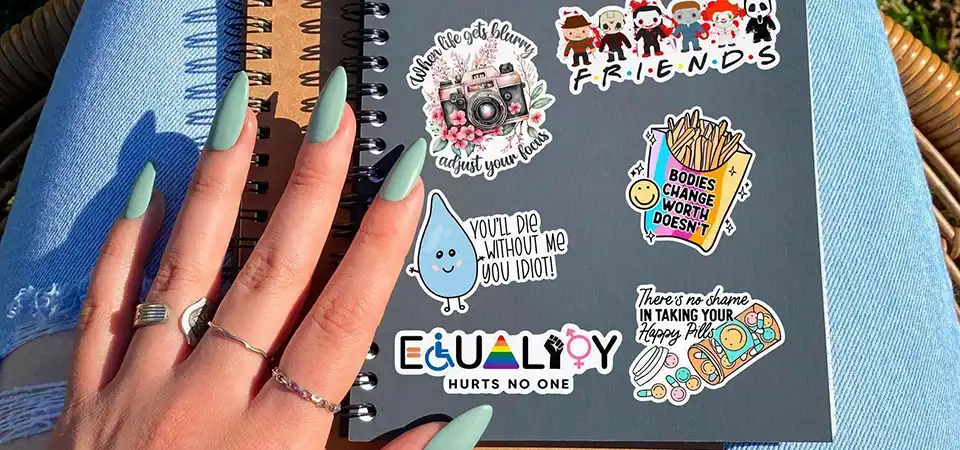

Get a die cut sticker when your design is the star and you want a premium, professional look. They are perfect for logos, character art, and retail handouts where presentation is the top priority.

For my clients attending trade shows or selling at markets, I almost always recommend die-cut stickers. They are a conversation starter. The unique shape makes people curious. Die cuts feel more valuable than a standard square sticker, so people are more likely to keep them and actually use them on a laptop or water bottle. This turns a simple handout into a walking advertisement. They are the clear winner when your goal is to impress. Look at the situations where they shine compared to their drawbacks.

| Pros of Die Cut | Cons of Die Cut |

|---|---|

| Professional, high-end appearance | Can be slightly more expensive |

| Makes your design stand out | Delicate shapes might be prone to bending |

| No distracting background border | Can be harder to peel for complex shapes |

| Ideal for handing out individually | Not suitable for sticker sheets |

Ultimately, if you want your sticker to be perceived as a gift or a piece of merchandise in itself, die cut is the way to go. It shows you invested in the details.

What are regular stickers?

You need a lot of stickers, and they have to be practical and affordable. You don't have a complex design, and a custom shape just isn't necessary.

Regular stickers, also called standard-cut stickers, are printed on a common shape like a square, rectangle, circle, or oval. The design sits inside this pre-set shape, often leaving a simple border.

Regular stickers are the workhorses of the sticker world. They are practical, efficient, and cost-effective. We call them "standard-cut" because they use basic geometric shapes that are fast and easy to produce in large quantities. There is no need to create a custom cutting path for each design. Think of simple bumper stickers, product information labels, or return address stickers. The focus isn't on creating a unique shape; it's on clearly communicating a message. For example, a bakery client of mine just needs a simple round sticker with their logo to seal their cookie bags. A fancy die cut shape isn't necessary and would slow down their packaging process. A roll of standard circular stickers is perfect for them—they are easy to peel, fast to apply, and get the job done effectively. They are the best choice when function and cost are more important than a unique form.

What other custom-cut sticker options are available?

A die cut sticker looks great, but you need something that's easier to peel or has multiple designs on one page. The options can feel overwhelming.

Besides die cut, the most popular option is the kiss cut sticker. This cut goes through the vinyl layer only, leaving the larger backing paper intact. This makes it easy to peel and protects intricate designs.

Kiss cut is my go-to recommendation for artists or businesses that need versatility. It's a fantastic middle ground that offers a custom shape with added practicality. It combines the best of both worlds, but it's important to understand how it differs from a die cut.

Die cut stickers vs. kiss cut stickers

The core difference is simple: how deep does the blade go? A die cut goes through everything. A kiss cut just "kisses" the surface. I made this table for my clients to help them visualize the difference.

| Feature | Die Cut Sticker | Kiss Cut Sticker |

|---|---|---|

| Cut-Through | Vinyl Layer + Backing Paper | Vinyl Layer Only |

| Final Product | Individual sticker in its exact shape | Custom-shaped sticker on a larger backing sheet |

| Peeling | Can be tricky with complex shapes | Very easy to peel |

| Protection | Edges are exposed | Protected by the surrounding backing paper |

When to get a kiss cut sticker

A kiss cut sticker looks exactly like a die cut sticker once you peel it and apply it. The difference is all in the delivery. I recommend kiss cuts in a few specific scenarios. First, for sticker sheets. You can fit multiple different designs on a single sheet, which is perfect for retail packs. Second, for very delicate designs. If you have a sticker with thin lines or sharp points, a die cut version might get bent or damaged. The kiss cut's backing paper acts as a protective frame. Finally, for speed. A client who applied thousands of labels to jars switched from die cut to kiss cut rolls. The easy-peel backing saved their team hours of work each week.

FAQs

Are die cut stickers more expensive?

They can be slightly more expensive than standard shapes because they require a custom cutting path for every design. However, with modern digital and laser cutting technology like we use, the price difference is often very small, especially on larger orders.

Can I get die cut labels?

Yes. In the world of roll labels, "die cut" usually refers to any custom shape that isn't a standard circle or square. The labels are cut to your unique shape but remain on a continuous roll for easy machine or hand application.

What is the difference between die cut and printed stickers?

This question mixes up two different processes. Printing is how the image gets on the vinyl. Die cutting is how the sticker is shaped after it's printed. All die cut stickers are printed first. The real question is often "die cut vs. a standard shape sticker," which this article covers.

Which cut type is best for stickers?

It depends entirely on your goal.

- Best for Presentation: Die Cut.

- Best for Easy Peeling & Protection: Kiss Cut.

- Best for Budget & High Volume: Standard Cut (square, circle, etc.).

What is the difference between die cut and standard cut?

This is the main point of our discussion. A die cut sticker is cut to the exact, custom shape of your artwork. A standard cut sticker is cut into a basic, default shape like a rectangle or an oval, regardless of the artwork's shape inside it.

Conclusion

Die-cut stickers offer a premium, custom shape perfect for branding. Regular and kiss-cut options provide practicality and easy peeling. Choose the cut that best fits your design's look and function.