You want a clean, professional logo on your product, but regular stickers have ugly backgrounds. This makes your brand look cheap and DIY, hiding the premium look of your item.

A cold transfer sticker, often called a UV DTF sticker, is a pressure-activated decal. It transfers just the ink design onto a surface using a clear film, leaving no background behind. It creates a seamless, printed-on look without using any heat.

I get a lot of questions about these stickers in my shop. They look incredibly professional, almost like they were printed directly on the object by a big factory. It's a huge step up from a traditional sticker with a white or clear border. But how do they work, and how are they different from the stickers you're used to? They're becoming one of my favorite ways to help brands create premium-looking products. Let's break it down.

How does a cold transfer sticker work compared to regular vinyl stickers?

Regular stickers leave a clear or white border around your design. This looks unprofessional and covers up the product's surface, cheapening the overall look and feel of your brand.

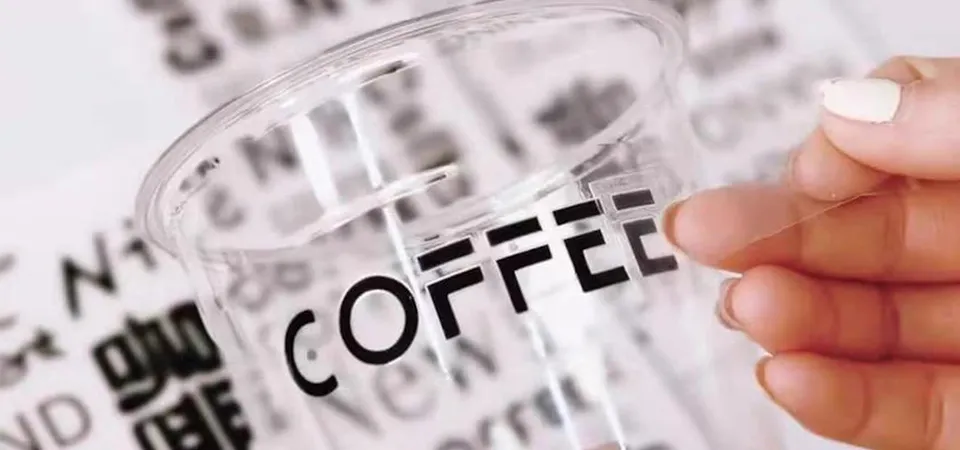

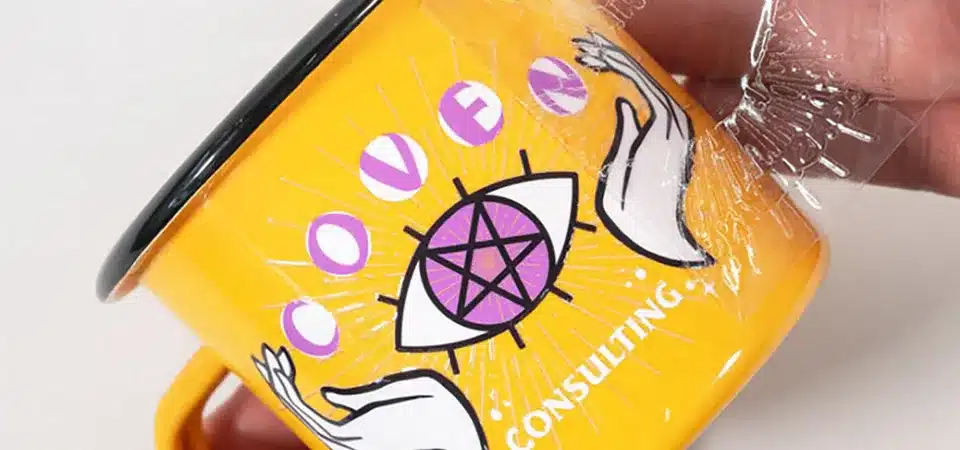

A cold transfer sticker uses a clear carrier film to press the ink design onto a surface. When you peel the film away, only the ink remains. Regular stickers have a backing layer that stays with the solid-piece sticker after application.

The biggest difference is what's left behind on your product. With a regular sticker, you get the whole shape. With a cold transfer, you get just the art. This fundamental difference in how they're built leads to a completely different result.

The Regular Sticker Experience

A classic vinyl sticker is a simple sandwich: it has a paper backing that you peel off, and the sticker itself, which is a single piece of vinyl with your design printed on it. The entire shape you ordered—circle, square, or custom shape—is what sticks to your surface. Even if parts of your design are clear, the sticker itself is still one solid piece of vinyl. It's great for many uses, but it will always look and feel like a sticker.

The Cold Transfer Sticker Process

A cold transfer is more like a temporary tattoo for objects. The process is a bit more involved but the result is amazing. The sticker arrives as a three-layer sandwich. You peel off the bottom protective sheet, place the design on your product, and rub it firmly with your fingers or a squeegee. This pressure activates the adhesive. Then, you carefully peel away the top clear carrier film. What's left behind is just the ink and adhesive in the shape of your design—no background, no clear film, nothing. It looks exactly like it was printed directly onto the surface.

What are the different types of transfer stickers?

You hear "transfer sticker" but don't know the difference between types. You might order the wrong one, wasting time and money on a product that's meant for a t-shirt, not a glass jar.

The main types are cold transfers (UV DTF), hot transfers (heat press vinyl), and die-cut vinyl transfers (vinyl lettering). Cold transfers use pressure, hot transfers use heat, and vinyl transfers are for simpler, single-color cut shapes.

The word "transfer" just means the design moves from a carrier sheet to the final product. But how it moves—with pressure, heat, or simple tape—is what defines the type and what you can use it for. As a printer, I have to be very clear with my clients about which one they need.

Cold Transfer (UV DTF)

These are for applying detailed, full-color logos and designs to hard, smooth surfaces. This is what we are talking about in this article. They are perfect for branding items like mugs, water bottles, phone cases, and packaging. The "cold" part is key because it means no heat is needed, so you can apply them to almost anything.

Hot Transfer (Heat Transfer Vinyl - HTV)

This type is exclusively for fabrics and textiles. It requires a special machine called a heat press to apply the design using both high temperature and pressure. This melts the adhesive on the back of the vinyl and fuses it into the fibers of a t-shirt, hat, or canvas bag.

Die-Cut Vinyl Transfer

This is the classic transfer decal you see for car window lettering or business hours on a glass door. A machine cuts letters or simple shapes from a sheet of solid-color vinyl. Transfer tape is applied over the top to keep all the separate pieces perfectly aligned during application.

What is the difference between cold transfer and hot transfer stickers?

You need a sticker for a delicate plastic item, but you're afraid a heat press will melt it. You feel stuck without a way to get a professional logo on your product.

Cold transfer stickers use pressure to apply, making them safe for heat-sensitive surfaces like plastic and glass. Hot transfer stickers require intense heat and pressure from a heat press, so they are only used for fabrics like cotton or polyester.

The application method is the biggest difference, and it determines everything. You can't mix them up. One uses your hands, and the other uses a heavy, hot machine.

The Cold Transfer Method: No Heat, All Pressure

I love these because they open up so many branding possibilities. We can put beautiful, full-color logos onto delicate electronics, thin plastics, or varnished wood without any risk of damage. The adhesive is specially formulated to bond using firm pressure alone. The process is simple and safe enough for anyone to do right at their desk. You just peel, stick, rub, and peel again. It’s a game-changer for small businesses wanting to create premium-looking products without expensive equipment.

The Hot Transfer Method: Heat is the Key

This is a completely different world, mainly for the apparel industry. Hot transfer material, usually called Heat Transfer Vinyl (HTV), has a heat-activated adhesive. To apply it, you must use a heat press that reaches temperatures over 150°C (300°F). The combination of heat and pressure melts the adhesive, forcing it to bond permanently with the fabric fibers. This is why it can survive many cycles in a washing machine. Trying to use this method on a plastic cup would just create a melted mess.

What materials are used in cold transfer stickers?

You want to order cold transfer stickers but don't know what they're made of. You worry about getting a low-quality product that won't last or won't look professional on your items.

Cold transfer stickers are a multi-layer system. They typically consist of a clear PET carrier film, UV-curable ink, an adhesive layer, and a PET release liner. The final "sticker" left on your product is just the ink and glue.

When clients ask me what these are made of, I tell them to think of it as a temporary "film sandwich." The materials you handle are just tools to get the design onto your product. The films get thrown away, and what's left is pure design.

The Film Sandwich Explained

Here's how I break it down for my customers:

- The Bottom Film (Release Liner): This is the protective backing paper. It's usually a PET film that protects the sticky adhesive layer before you're ready to apply the sticker. You peel this off first and discard it.

- The "Middle" (The Design): This isn't one layer, but several micro-layers printed at once. It's a combination of durable, UV-cured inks that create the color, and a special adhesive printed right alongside it. This fusion of hardened ink and glue is what actually stays on your product.

- The Top Film (Carrier Film): This is the clear sheet on top. Its job is to hold all the separate parts of your design together in perfect alignment. After you rub the design onto your product, you peel this carrier film off, and it leaves the ink and glue behind.

So, while the product you hold is made of PET films, the final result on your item is a sleek, durable layer of pure ink.

Are cold transfer stickers durable and waterproof?

You're excited to use a cold transfer sticker but worry it will wash off or scratch easily. This makes you hesitant to use it on high-use items like a water bottle or phone.

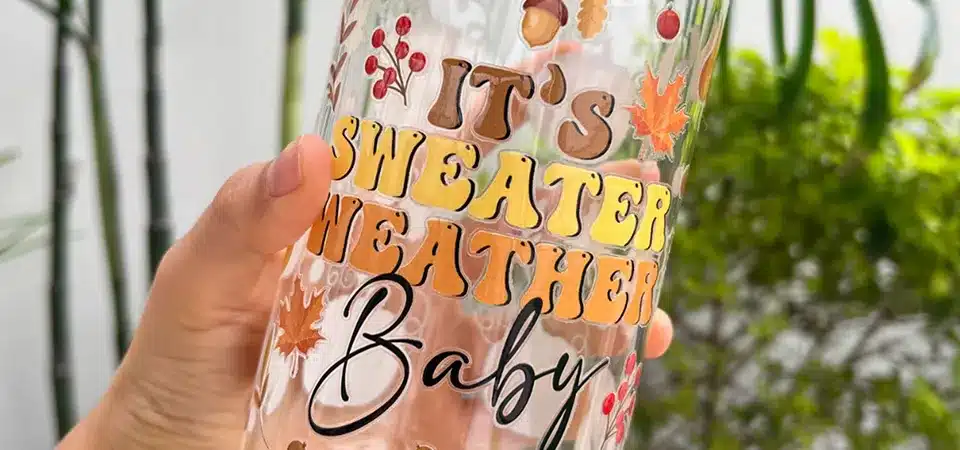

Yes, they are waterproof and very scratch-resistant, perfect for indoor and light outdoor use. While durable, they aren't as tough as laminated vinyl for extreme conditions like a car bumper, but they are great for mugs, laptops, and most products.

I've tested these things extensively in my shop because durability is everything. The short answer is that they are much tougher than people expect them to be. The UV curing process makes the ink incredibly hard and resilient.

How Tough Are They Really?

Once applied correctly to a proper surface, the design forms a very hard, durable layer. They are completely waterproof, which means you can hand-wash a mug or water bottle with a cold transfer sticker on it without any issues. They are also surprisingly scratch-resistant. I tried scratching one on my desk with my fingernail and a key, and it didn't leave a mark unless I used extreme force. The bond is very strong.

However, it's important to have the right expectations. A cold transfer sticker is still a very thin layer of ink. For an application that faces extreme-long-term abuse—like a decal on a car bumper that deals with rock chips, road salt, and harsh sun for years—I would still recommend our thick, heavy-duty laminated vinyl stickers. But for almost everything else, like branding products, personalizing electronics, or decorating glassware, their durability is more than enough and they look far more professional.

What surfaces can cold transfer stickers be applied to?

You have a great design, but you don't know what surfaces a cold transfer sticker will stick to. You're afraid to place an order only to find out it won't work on your product.

Cold transfer stickers work best on smooth, hard, non-porous surfaces. This includes glass, metal, plastic, glossy painted wood, and ceramic. They will not stick well to fabric, raw wood, leather, or heavily textured surfaces.

The key to a successful application is a smooth, clean surface. The adhesive on these stickers needs as much surface area as possible to form a strong bond. Think of it like trying to stick tape to a basketball versus a pane of glass—it sticks much better to the smooth glass.

Surfaces That Work Great

- Glass: Jars, windows, drinkware.

- Metal: Stainless steel water bottles, metal tins, laptops.

- Plastics: Phone cases, product packaging, acrylic sheets.

- Ceramics: Glossy mugs, tiles (not matte or porous ones).

- Sealed Wood: Any wood with a smooth, glossy or semi-gloss finish.

Surfaces to Avoid

The process will fail on the wrong surface, so it's important to know what not to do.

- Fabric & Leather: The adhesive is not designed for porous, flexible fibers.

- Unsealed, Raw Wood: The surface is too porous and uneven for the adhesive to grab onto.

- Textured or Powder-Coated Finishes: These surfaces are very popular on some water bottles. The sticker can only stick to the "peaks" of the texture, not the "valleys," which results in a weak bond that will peel easily.

If you're ever unsure about a surface, my advice is always the same: test one sticker on it first before you commit to applying all of them.

Conclusion

Cold transfer stickers offer a professional, no-background look for hard goods. They are durable, waterproof, and easy to apply with pressure, making them a fantastic modern branding choice.