As a factory that has specialized in sticker printing for years, I deal with customers from all kinds of industries every day—startups, online sellers, wholesalers, brand owners, designers, and more. And they all ask the same question: "Is there a way to print stickers cheaper?"

The answer is yes. And the good news is, there are more ways than you'd think. Cheap doesn’t have to mean poor quality. It’s all about how you optimize your printing and ordering process. Today, I’m sharing the most practical, real-world tips I’ve learned from working with thousands of sticker orders. These tips will help you save money without compromising on quality.

Choose the Right Printing Method

Not all printing methods are created equal. Choosing the wrong method could cost you 2-3 times more than necessary.

Digital Printing vs. Offset Printing:

- Digital printing is great for small runs, variable designs, and personalization. There’s no setup cost, so even 50 pieces are affordable.

- Offset printing is best for large, consistent orders. The upfront cost (like plate-making) is higher, but the unit price drops significantly as volume increases.

In short: If you're printing small batches, go digital. For big orders, offset is your friend.

UV, Screen, and Thermal Transfer:

- UV printing prints directly on various materials and is durable. Great for premium products.

- Screen printing is dirt cheap for single-color, bulk runs.

- Thermal transfer is used for special cases like high-temperature or industrial labels. It's more expensive.

My take: For most regular sticker orders, digital or offset printing offers the best cost-efficiency.

Design Smart to Reduce Costs

Your sticker design directly impacts your final cost. Here are practical ways to make your design cheaper:

Simplify Colors:

More colors = higher cost. This is especially true in screen and offset printing. Even for digital, heavy ink use increases cost.

Standardize Sizes and Shapes:

Avoid using many different sizes in the same order. Standard circles, squares, or rectangles are cheaper than custom die-cuts.

Avoid Complex Die-Cuts:

Intricate shapes require custom dies, which add extra cost. Go with simple rounded corners or standard curves.

Consider Slightly Smaller Sizes:

Sometimes reducing sticker size by just 1 cm lets us fit more stickers per sheet. That alone can cut costs by 10-20%.

Materials: Balancing Cost and Durability

Sticker materials affect pricing more than you might think.

Substrate:

- Paper-based (e.g. kraft, coated paper): cheapest, good for indoor use or promos.

- PVC vinyl: waterproof and weather-resistant. Great balance between cost and quality.

- PET: more durable, but more expensive. Often used in electronics or harsh environments.

Lamination:

- Glossy/Matte: basic protection, very affordable.

- Textured or Holographic: looks great but costs 20-50% more.

- Anti-scratch/UV-resistant: for long-term outdoor use, pricier but worth it if needed.

Adhesive:

- Standard permanent: works for most use cases.

- Removable: slightly more expensive.

- High-tack: specialty usage, highest cost.

Pro Tip: For most orders, go with PVC + gloss lamination + standard adhesive. It's affordable, durable, and versatile.

How to Negotiate with Your Sticker Supplier

Knowing the right questions to ask can save you a lot.

Ask for:

- Existing die sizes (to avoid mold fees)

- Gang printing options (combine designs to save)

- Promo or clearance materials

- Batch ordering discounts (mix styles in one print run)

Long-Term vs. One-Off Orders:

Regular, ongoing orders often qualify for better pricing. Let your supplier know your growth plans.

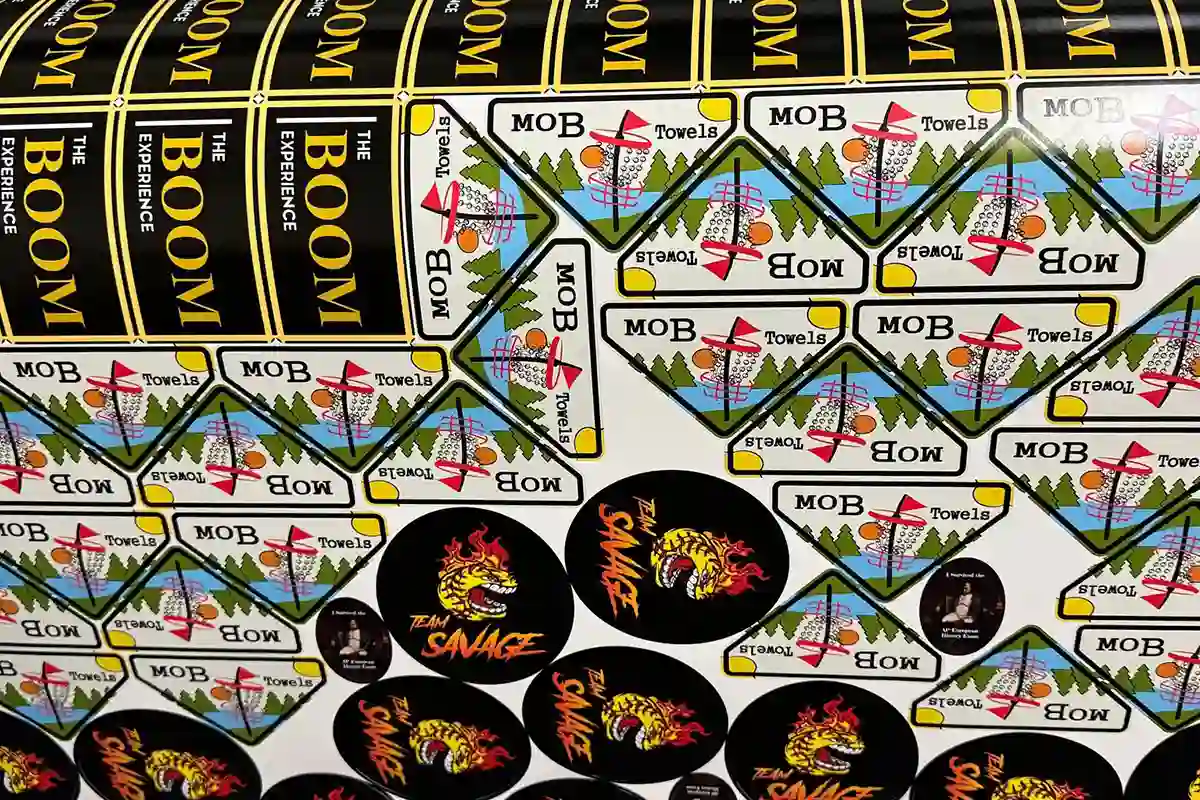

Combine Orders to Save:

If you have five designs and need 500 pcs of each, ask to print them all together. This reduces setup costs and lowers unit prices.

Shipping & Logistics Cost-Saving Tips

Sticker unit cost may be low, but international shipping can eat your margin fast.

Order in Bulk:

Larger shipments cost less per kg. Avoid multiple small shipments.

Use Affordable Shipping Channels:

- Sea freight > air cargo > express (cheapest to most expensive)

- Use express only for urgent orders.

Pack Smart:

Optimizing how stickers are packed helps reduce volume and weight.

Use Local Warehousing if Possible:

For Amazon, Etsy, or Shopify sellers: Ship in bulk to a fulfillment center or prep center and distribute from there.

Finding the Right Supplier

Cheap doesn’t mean low quality—but you have to find the right partner.

Overseas (e.g., China) vs. Local Printers:

- China offers unbeatable bulk prices, fast turnaround, and global delivery.

- Local printers may be better for quick samples or urgent runs.

Best strategy: Sample locally, bulk order overseas.

Vet Your Supplier:

- Do they have English-speaking sales support?

- Are quotes detailed and transparent?

- Can they show certifications and actual product photos?

- Do they offer pre-production samples?

Red Flags:

- Prices too good to be true

- No company details or unclear timelines

- No revisions or sample guarantees

Common Mistakes That Waste Money

Some "cost-saving" moves can backfire:

Over-Negotiating:

Too low a price might force a supplier to use lower-grade material or skip quality checks.

Hidden Charges:

Watch for mold fees, VAT, shipping, color matching charges, etc. Always ask for an all-in quote.

Micro Orders:

Constantly ordering tiny batches increases per-unit cost due to setup and labor. Better to consolidate orders.

Use the Savings to Build Your Brand

Smart clients use the money they save to add real value.

Upgrade Packaging:

Branded paper bags, thank-you cards, and custom seals go a long way in boosting brand image.

Include Free Samples:

Give customers extra stickers as a surprise bonus. It helps with customer retention and social shares.

Tell Your Story:

Insert a card with your brand mission or usage tips. Builds trust and connection.

Conclusion

Getting cheap stickers is not about cutting corners—it's about making smarter decisions at every step. From printing method to design, material, negotiation, and shipping, there are multiple ways to save without sacrificing quality.

I hope these tips help you make better decisions for your next order. If you ever need help optimizing your custom sticker project, feel free to reach out. Remember, we're not just printing stickers. We're helping you build a better, more affordable brand.