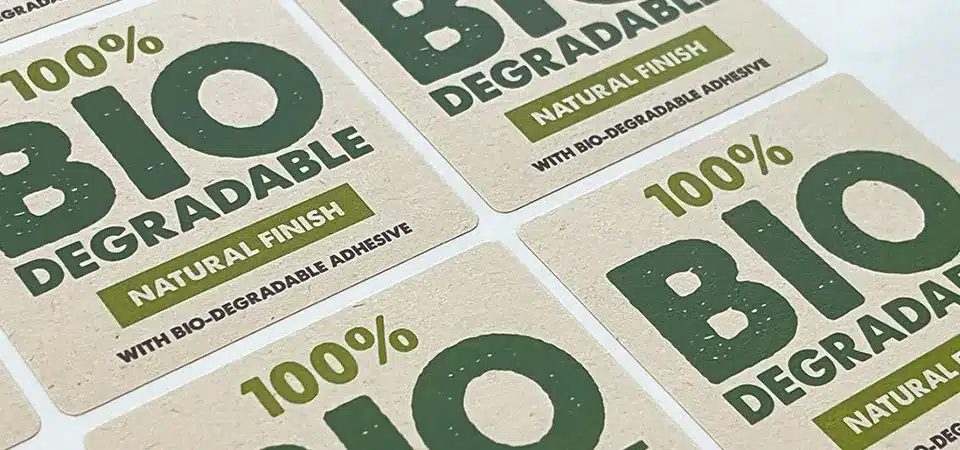

You want eco-friendly stickers for your brand, but worry they aren't truly sustainable or durable. Choosing the wrong "green" option can be worse than doing nothing.

Biodegradable paper stickers are an eco-conscious alternative to vinyl, made from sustainable materials like sugarcane fiber, bamboo, or recycled paper. They are designed to break down naturally in a compost environment, reducing landfill waste and aligning your brand with sustainable practices.

As a sticker printer, I’ve seen a huge shift towards sustainable materials. Clients are asking for greener options more than ever before. But the term "biodegradable" can be confusing. It's not just about the sticker itself; it's about the entire life cycle, from the raw material to what happens after you throw it away. Let's break down everything you need to know to make an informed choice for your business.

What are biodegradable paper stickers made from?

The term "paper" is vague, and you worry you might be buying something that isn't as green as you think. This uncertainty can undermine your brand's eco-friendly claims.

Biodegradable paper stickers are made from plant-based materials like sugarcane fiber (also known as bagasse), bamboo, or post-consumer recycled paper. These materials are chosen because they are renewable and can break down naturally in a compost environment.

When clients ask for an eco-friendly paper sticker, they're looking for an alternative to two things: traditional paper from virgin forests and plastic vinyl. The materials we use for these biodegradable stickers are specifically chosen to address those concerns. It’s all about finding resources that are kinder to our planet.

Common Eco-Friendly Materials

- Sugarcane Fiber (Bagasse): This is my personal favorite. It's not made from the sugarcane plant itself, but from the leftover pulp after the juice has been extracted. It’s a brilliant way to upcycle an agricultural waste product into something useful.

- Bamboo: Bamboo is a type of grass that grows incredibly fast, requires no pesticides, and can be harvested without killing the plant. It's a highly renewable resource for making paper.

- Recycled Paper: This option gives a second life to paper that would otherwise end up in a landfill. It reduces the demand for new trees and saves a significant amount of water and energy compared to making virgin paper.

Each of these materials provides a textured, natural feel that instantly communicates a commitment to sustainability.

What is sugarcane paper, exactly?

You've heard the term "sugarcane paper," but it sounds strange. Is it just a marketing gimmick, or is there something real behind it?

Sugarcane paper is made from bagasse, the fibrous pulp that is left over after sugarcane stalks are crushed to extract their juice. It is a completely tree-free paper made by repurposing an agricultural byproduct that would otherwise be discarded.

The story behind sugarcane paper is what makes it so compelling. For years, after sugar mills crushed the sugarcane, the leftover bagasse was often burned or thrown away. It was considered waste. Now, we have a process to turn that fibrous material into high-quality paper.

From Plant to Paper

The process is a fantastic example of a circular economy. First, the sugarcane is grown and harvested for the sugar industry. Once the sweet juice is pressed out, the remaining dry pulp, the bagasse, is collected. Instead of becoming waste, it's sent to a paper mill. There, it's mixed with water to create a pulp, which is then pressed, dried, and rolled into paper, ready for us to print on. By choosing sugarcane paper stickers, you're not just avoiding trees; you're actively helping to reduce agricultural waste. It’s a smart and sustainable choice that I love explaining to my clients.

What is the life cycle of a biodegradable paper sticker?

You want to be sure that your "eco" sticker truly disappears. Many green products sound good but still end up polluting the environment in a landfill.

The life cycle starts with a renewable resource like sugarcane. After its use, the sticker is composted, where microorganisms break it down into natural elements like water and biomass, enriching the soil instead of polluting it.

To understand the real benefit, you have to look at the entire journey of the sticker, from its creation to its disposal. It’s a very different story from a plastic vinyl sticker.

From Creation to Compost

- Resource: The journey begins with a fast-growing, renewable plant like sugarcane.

- Production: The agricultural byproduct (bagasse) is turned into paper, avoiding waste and the need to cut down trees.

- Use: You apply the sticker to your product packaging, giving it a natural, eco-friendly look.

- Disposal: Your customer receives the package and, instead of putting it in the trash, can place the sticker (along with the compostable box) into a home or industrial compost bin.

- Decomposition: In the compost pile, microorganisms get to work. Over a few months, they break the sticker down into its natural components.

- End Result: The sticker becomes part of nutrient-rich compost, which can be used to fertilize soil.

A vinyl sticker, in contrast, would sit in a landfill for hundreds of years, potentially leaching chemicals. The biodegradable life cycle is designed to give back to the earth, not take from it.

Is sugarcane truly an eco-friendly material?

"Eco-friendly" is a big claim. You're rightfully skeptical and want to make sure you're not just falling for a clever marketing tactic or "greenwashing."

Yes, sugarcane is a highly eco-friendly raw material. It's a fast-growing, renewable resource that requires relatively little water and no replanting after harvest. Using its byproduct, bagasse, also reduces agricultural waste, making it a very sustainable choice.

I always encourage my clients to ask these tough questions. True sustainability holds up to scrutiny. When we look at sugarcane, its green credentials are very strong.

Evaluating Sugarcane's Green Credentials

Sugarcane is what's known as a C4 plant, which means it's very efficient at photosynthesis and uses water more effectively than many other crops. More importantly, it’s a powerhouse of renewability. A sugarcane field can be harvested annually for several years without needing to be replanted because the root system remains intact and regrows. This reduces soil erosion and the fuel needed for farming. The best part, from my perspective as a printer, is that we are using the waste from this already efficient process. We aren't driving the demand for more sugarcane to be planted; we are simply making better use of what's already there. Compared to logging decades-old forests for paper, it's a massive improvement.

What are the pros and cons of sugarcane paper?

No material is perfect. You need to understand the full picture—both the good and the bad—before committing your brand's reputation and budget to it.

The main pros are its sustainability, biodegradability, and premium, textured feel. The primary con is its lower durability and lack of water resistance compared to plastic vinyl, making it unsuitable for products that face moisture or heavy handling.

Honesty is key when talking about sustainable materials. Sugarcane paper is a fantastic option, but it's not the right choice for every single application. Here's the balanced view I give my clients.

A Balanced View

| Pros | Cons |

|---|---|

| Sustainable Source: Made from a renewable, fast-growing agricultural waste product. | Not Waterproof: It is still paper and will be damaged by prolonged exposure to water. |

| Biodegradable: Breaks down in a compost environment, leaving no toxic residue. | Less Durable: It's not as tear-proof or scuff-resistant as a vinyl sticker. |

| Tree-Free: Helps reduce deforestation and protects natural habitats. | Requires Compost: It only biodegrades properly in a compost environment, not in a landfill. |

| High-Quality Look: Has a beautiful, natural texture that signals quality and eco-friendliness. | Slightly Higher Cost: Can sometimes be more expensive than basic paper, but the gap is closing. |

Choosing sugarcane paper is about aligning the material with its purpose. For the right product, its pros overwhelmingly outweigh its cons.

When should you use biodegradable paper stickers?

You have these great eco-friendly stickers, but where do they fit best? Using them on the wrong product could lead to failure and disappointed customers.

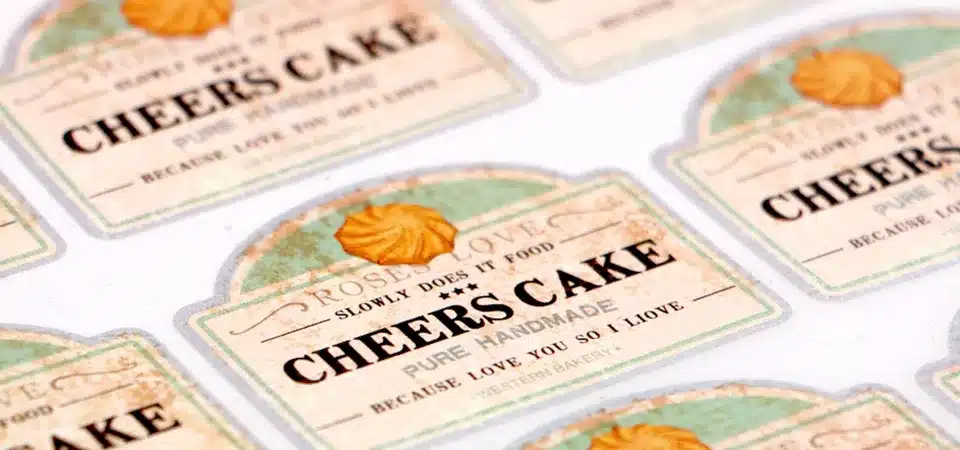

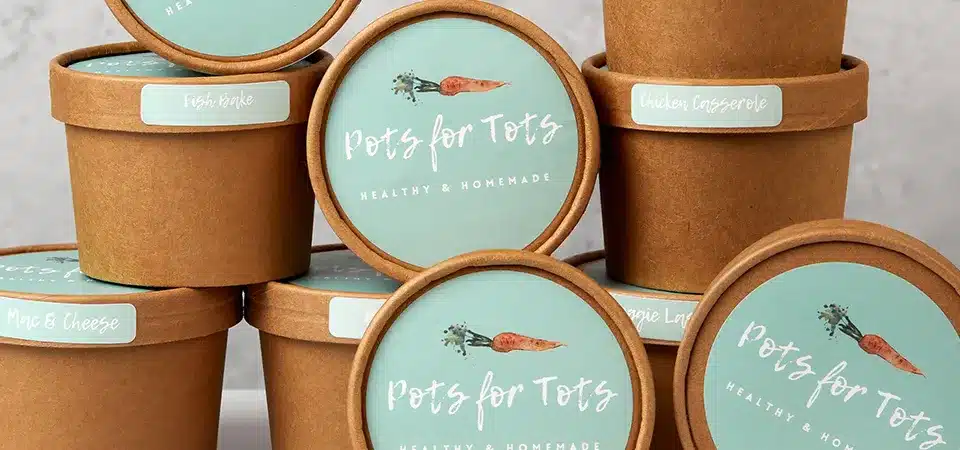

Use biodegradable paper stickers for short-term applications on dry goods where sustainability is a core part of your brand's message. They are perfect for organic product packaging, sealing shipping boxes, coffee bags, or candle labels.

The key is to match the sticker's strengths to the product's needs. Since these stickers are not waterproof or super durable, you wouldn't want to put them on a shampoo bottle that lives in the shower or on a car bumper.

Ideal Applications

Here are the types of businesses and uses where I see these stickers succeed most often:

- Eco-Conscious Brands: This is the most obvious fit. If your brand is built on being natural, organic, or sustainable, these stickers are a must. Think coffee roasters, handmade cosmetic brands, or organic food producers.

- Packaging Seals: They make a beautiful and eco-friendly seal for tissue paper, gift boxes, or paper mailer bags.

- Dry Goods Labeling: They are perfect for products that won't be exposed to moisture. This includes candle boxes, soap wraps, clothing hang tags, and bakery bags.

- Short-Term Use: For products with a quick turnaround, like items sold at a farmers' market or for event-specific branding, these stickers are a great choice. The sticker's lifespan matches the product's.

It's all about sending a consistent message. A sustainable sticker on sustainable packaging tells a powerful story.

What do biodegradable paper stickers cost?

You're worried that choosing an "eco-friendly" option will be too expensive, and a tight budget might force you to stick with less sustainable plastic options.

Biodegradable paper stickers are often slightly more expensive than standard paper but are generally comparable to or even cheaper than high-quality vinyl. The price reflects the specialized material, but the cost difference is becoming smaller as they grow in popularity.

This is a question every small business owner has to ask. The good news is that "eco-friendly" no longer automatically means "expensive." As demand for sustainable materials like sugarcane paper has grown, the production has become more efficient, and prices have come down.

Understanding the Price Tag

When you get a quote, the price will be based on a few factors: the size of the sticker, the quantity you order, and the complexity of the shape. In general, sugarcane paper sits in a very reasonable middle ground. It's a premium paper option, so it costs a bit more than the most basic, non-recycled paper. However, it's usually more affordable than durable, laminated vinyl stickers designed for outdoor use. Many of my clients see the small extra cost not as an expense, but as an investment. It's an investment in their brand's values and in attracting customers who are willing to pay for products that align with their own principles.

What about the backing paper? Is it compostable too?

You think you have the perfect compostable sticker. But then you peel it off, and the shiny backing paper feels like plastic, potentially ruining your sustainable efforts.

This is the biggest challenge. Most sticker backing paper has a silicone coating to allow for easy peeling, which makes it non-compostable and non-recyclable. While the sticker itself biodegrades, the liner almost always ends up in a landfill.

This is the part of the conversation where I have to be completely honest with my clients. It's a frustrating, industry-wide problem. That slick, shiny surface on the back of any sticker is a "release liner." It's almost always paper coated with a thin layer of silicone. Without that silicone, the adhesive would be permanently stuck to the backing paper.

The Sustainability Sticking Point

Unfortunately, that silicone coating makes the liner impossible to recycle in most facilities and also prevents it from breaking down in a compost pile. So, even when you choose a beautiful biodegradable sticker, you are still left with a piece of waste. It’s a major sticking point in our journey to a fully sustainable label. The good news is that the industry is aware of this. New technologies are emerging, including compostable release liners made from PLA (a plant-based plastic) or other specially treated papers. They are still rare and more expensive, but as a printer, I am constantly searching for these innovations to offer my clients. It’s the final piece of the puzzle to create a truly zero-waste sticker.

Conclusion

Biodegradable paper stickers are a fantastic eco-choice for dry goods, enhancing brand value. However, be aware that the backing paper is typically not compostable—a current industry challenge.